Boat flooring is an essential part of any vessel, providing safety, comfort, and durability. One of the most popular materials used today is EVA (Ethylene Vinyl Acetate) foam, known for its softness, shock-absorbing properties, and slip-resistant texture. However, as sustainability and environmental awareness become increasingly important for consumers, questions arise about the environmental impact of EVA foam. In this article, we’ll dive deep into the environmental implications of using EVA foam for boat flooring and explore whether it’s a sustainable option for the marine industry.

What is EVA Foam?

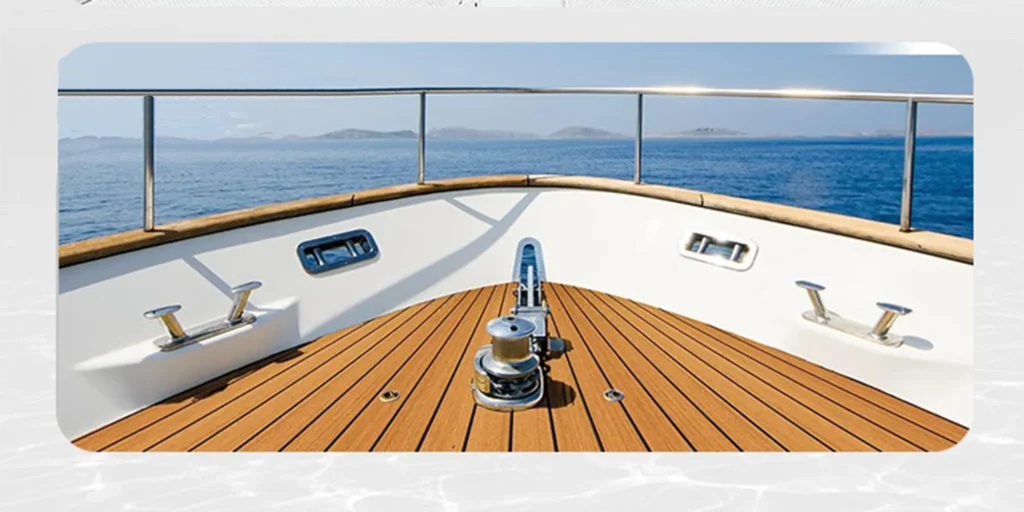

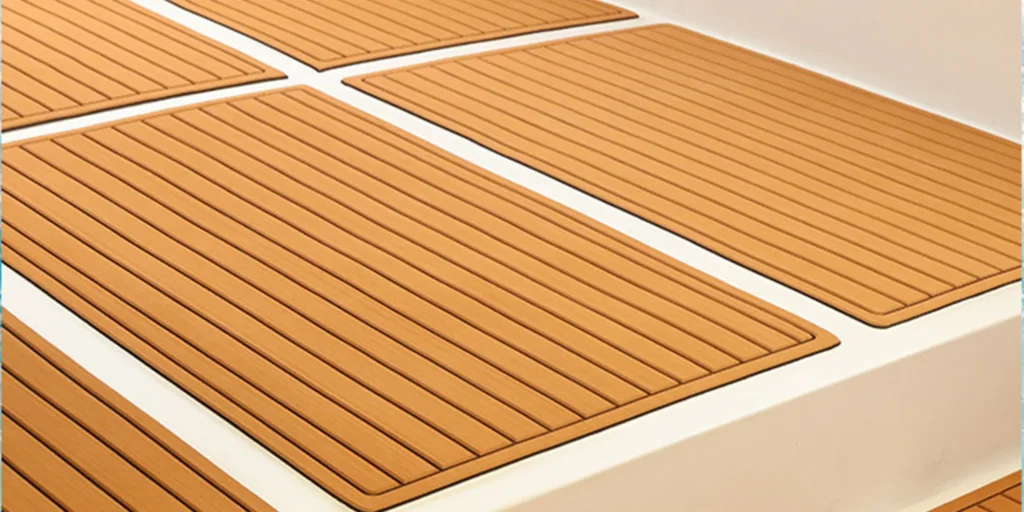

EVA foam is a polymer blend of ethylene and vinyl acetate, commonly used in a wide range of products, including shoes, yoga mats, and, of course, boat flooring. Its popularity in the boating world comes from its durability, resistance to water and UV rays, and its comfort underfoot. EVA foam is easy to clean, install, and maintain, making it a convenient option for boat owners.

However, as with any synthetic material, it’s important to assess the environmental footprint of EVA foam, especially in comparison to traditional boat flooring materials such as teak wood or fiberglass.

Production Process and Environmental Concerns

The first environmental concern surrounding EVA foam lies in its production. EVA is produced through polymerization, a chemical process that involves the transformation of ethylene and vinyl acetate into the foam material we see in boat flooring. This process requires a significant amount of energy and relies on petroleum-based raw materials, making it a less sustainable option compared to natural alternatives.

In addition, the production of EVA foam can result in the emission of volatile organic compounds (VOCs), which contribute to air pollution. The chemicals used in the manufacturing process may also have adverse effects on ecosystems if they are not managed properly.

Non-Biodegradable Nature of EVA Foam

One of the biggest environmental drawbacks of EVA foam is that it is non-biodegradable. This means that once it reaches the end of its lifecycle, EVA foam does not naturally break down into the environment. As a result, EVA foam products that are discarded improperly can contribute to landfill waste, marine pollution, and the broader problem of plastic waste in our oceans.

For boat flooring, this poses a particular concern because old EVA foam panels are often discarded when boats are refurbished or upgraded. If not recycled or disposed of responsibly, these discarded pieces can accumulate in landfills or end up in the ocean, harming marine life.

Recycling Challenges

While EVA foam is technically recyclable, the infrastructure to recycle this material is limited. The foam is often combined with other materials such as adhesives, making it difficult to process in traditional recycling facilities. Furthermore, the recycling process itself can be energy-intensive and costly, discouraging widespread adoption.

Despite these challenges, some companies are working on developing more effective recycling systems for EVA foam products. Initiatives that collect and recycle EVA foam boat flooring are emerging, but they are not yet widespread or easily accessible for the average consumer.

Comparison to Alternative Boat Flooring Materials

Teak Wood

Teak is one of the most common alternatives to EVA foam in boat flooring, prized for its natural durability and aesthetic appeal. Unlike EVA foam, teak is biodegradable and can be sustainably sourced if harvested from responsibly managed forests. However, teak comes with its own set of environmental concerns, such as deforestation and the carbon footprint associated with transporting it from tropical regions to boat manufacturers and consumers worldwide.

Fiberglass

Fiberglass is another widely-used material in boat flooring, offering strength and resilience. However, fiberglass production involves energy-intensive processes, and like EVA foam, it is not biodegradable. Additionally, fiberglass fragments can pose environmental risks when discarded improperly, contributing to marine pollution.

Compared to these alternatives, EVA foam offers a lightweight and low-maintenance option but falls short in terms of sustainability due to its synthetic nature and recycling challenges.

Efforts Toward Eco-Friendly EVA Foam

As environmental concerns grow, there has been a push for developing more sustainable EVA foam products. Some manufacturers are exploring the use of bio-based EVA foam, which incorporates renewable materials such as plant-based resins. This reduces the reliance on petroleum-based components and helps to lower the carbon footprint of production.

Additionally, there are efforts to create more eco-friendly adhesives and coatings used in conjunction with EVA foam flooring. These innovations aim to reduce the emission of harmful chemicals and improve the overall environmental profile of EVA foam.

What Can Consumers Do?

For boat owners who prefer EVA foam flooring for its practical benefits, there are steps that can be taken to minimize its environmental impact:

- Choose eco-friendly brands: Look for manufacturers that use sustainable practices and bio-based EVA foam products.

- Proper disposal: When it’s time to replace your EVA foam flooring, ensure that it is disposed of responsibly. Check for recycling programs that accept EVA foam or collaborate with companies that offer take-back services for used flooring.

- Extend the lifespan: Take good care of your EVA foam flooring by cleaning it regularly and protecting it from excessive UV exposure, which can prolong its life and reduce the frequency of replacement.

EVA foam boat flooring offers numerous practical advantages, including comfort, durability, and ease of use. However, like many synthetic materials, it comes with environmental concerns, particularly in terms of production and disposal. While EVA foam is not biodegradable and recycling infrastructure is limited, there are emerging efforts to make this material more eco-friendly.

Boat owners who prioritize sustainability should weigh the pros and cons of EVA foam against alternative materials and explore eco-friendly options where possible. By choosing responsible manufacturers and practicing proper disposal, consumers can enjoy the benefits of EVA foam while minimizing its environmental impact.

FAQ:

- Is EVA foam boat flooring eco-friendly?

EVA foam boat flooring has environmental challenges due to its petroleum-based components and non-biodegradable nature. However, there are emerging efforts to make it more eco-friendly through bio-based alternatives and recycling initiatives. - Can EVA foam be recycled?

Yes, EVA foam is technically recyclable, but recycling options are limited due to the foam’s combination with other materials like adhesives. Specialized recycling programs are required for proper disposal. - How does EVA foam compare to other boat flooring materials environmentally?

Compared to teak wood and fiberglass, EVA foam has a lower maintenance need but a higher environmental impact due to its synthetic origin and recycling challenges. Teak is biodegradable, and fiberglass is durable but non-biodegradable. - What are the benefits of using EVA foam for boat flooring?

EVA foam provides comfort, slip-resistance, shock absorption, and UV protection. It’s also lightweight and easy to install, making it a practical choice for many boat owners. - How can I reduce the environmental impact of using EVA foam flooring?

To minimize the environmental footprint, choose brands that offer eco-friendly or bio-based EVA foam products, dispose of old flooring through recycling programs, and take steps to extend the lifespan of your flooring by protecting it from UV damage.

#EVAfoam #BoatFlooring #Sustainability #EcoFriendlyBoating #MarinePollution #GreenBoating #Recycling #SustainableLiving #BoatOwners #EnvironmentalImpact

WELLE Trade has over 20 years of experience in the production and processing of PE/EVA/TPE foams, so you may want to consult with them if you have any sourcing needs.