Abstract

Ethylene-vinyl acetate copolymer (EVA Foam), a high-performance foam material, has emerged as a transformative solution in the packaging sector in recent years. Its exceptional shock absorption, lightweight properties, chemical resistance, and recyclability make it an ideal choice for safeguarding precision instruments, electronic devices, medical equipment, and more. This article delves into the specific applications, technological advantages, and future prospects of EVA Foam in packaging, while addressing frequently asked questions to offer businesses scientifically grounded insights for material selection.

Core Advantages of EVA Foam in Packaging

1. Superior Cushioning and Impact Resistance

The closed-cell structure of EVA Foam absorbs up to 90% of impact energy. For instance, a leading smartphone manufacturer reported a 58% reduction in transit damage after adopting custom EVA inserts. Its adjustable density (20–200 kg/m³) caters to diverse load-bearing requirements.

2. Lightweight Design and Cost Efficiency

Compared to traditional wood or EPE foam, EVA reduces packaging weight by over 30%, significantly lowering transportation energy consumption. A global logistics firm documented 12% savings per container shipment after switching to EVA.

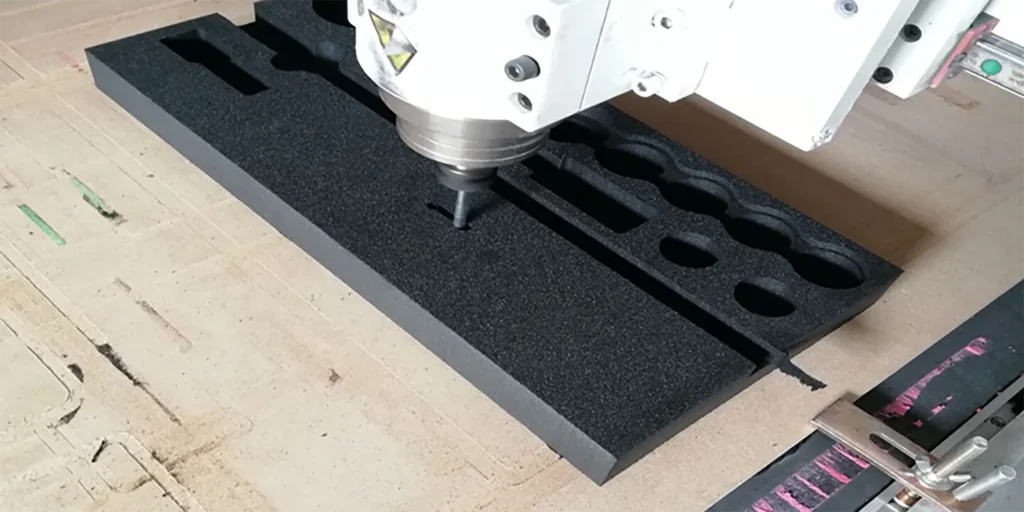

3. Customizable Fabrication Techniques

Utilizing CNC cutting, thermoforming, or injection molding, EVA precisely conforms to product contours. Tesla’s precision automotive components, for example, employ 3D-scanned EVA supports with tolerances within ±0.2mm.

4. Eco-Conscious Compliance

Meeting REACH and RoHS standards, manufacturers have developed biodegradable EVA formulations. Global EVA recycling rates reached 21% in 2023, projected to exceed 35% by 2026.

Key Applications

- Premium Electronics: Apple’s MacBook Pro utilizes dual-layer EVA construction, passing drop tests from 1.5 meters.

- Medical Logistics: Johnson & Johnson’s vaccine carriers combine EVA with phase-change materials to maintain 2–8°C for 72 hours.

- Industrial Component Protection: Siemens’ gas turbine blade packaging integrates EVA with carbon fiber for dual shockproof and anti-corrosion performance.

FAQ: Common Queries on EVA Packaging Foam

Q1: Is EVA foam packaging more expensive than conventional alternatives?

Initial costs are 15–20% higher, but reduced transit damage, reusability (8–10 cycles), and brand enhancement yield over 40% ROI long-term.

Q2: Does EVA comply with EU environmental regulations?

Premium EVA foam emits <0.5mg/m³ VOCs (SGS-certified) and holds FDA food-contact approval, making it suitable for pharmaceutical packaging.

Q3: Can EVA meet anti-static requirements?

Yes. Incorporating carbon fibers (conductivity: 10³–10⁶ Ω/sq) or anti-static agents achieves surface resistance of 10⁶–10⁹ Ω, ideal for ESD-sensitive components.

Q4: How does EVA perform under extreme temperatures?

Industrial-grade EVA retains elasticity between -40°C and 80°C, with Arctic equipment suppliers verifying 3x better crack resistance than PU foam at -60°C.

Q5: What advantages does EVA offer over EPE foam?

50% faster rebound and superior print adhesion (cross-cut test: 4B rating), ideal for luxury branding.

Q6: Minimum order quantity (MOQ) and lead times?

Standard MOQ: 500 units; custom mold development: ~15 days, with 48-hour rapid prototyping for 3D files.

Q7: How to determine EVA density grades?

Per ASTM D3574, 20–50D suits lightweight accessories, 80–120D for laptops, and 150D+ for automotive parts.

Industry Outlook

Grand View Research estimates the global EVA packaging market at $4.7 billion in 2023, growing at 6.8% CAGR. Emerging innovations include:

- Smart EVA with embedded temperature/humidity sensors

- Self-healing foam (microcapsule technology)

- Flame-retardant EVA for solar panel transport (UL94 V-0 certified)

Through technological advancements and circular economy models, EVA Foam is redefining packaging value chains, delivering robust support for corporate sustainability goals.

WELLE Trade has over 20 years of experience in the production and processing of PE/EVA/TPE foams, so you may want to consult with them if you have any sourcing needs.