When it comes to foam materials, TPE (Thermoplastic Elastomer) foam is rapidly gaining popularity due to its impressive combination of flexibility, durability, and sustainability. However, it’s essential to understand how TPE compares to other widely-used foams like EVA (Ethylene Vinyl Acetate), PVC (Polyvinyl Chloride), and other popular options. This article will dive deep into a comparative analysis of TPE foam against these materials, focusing on key aspects such as performance, durability, sustainability, and overall versatility.

What is TPE Foam?

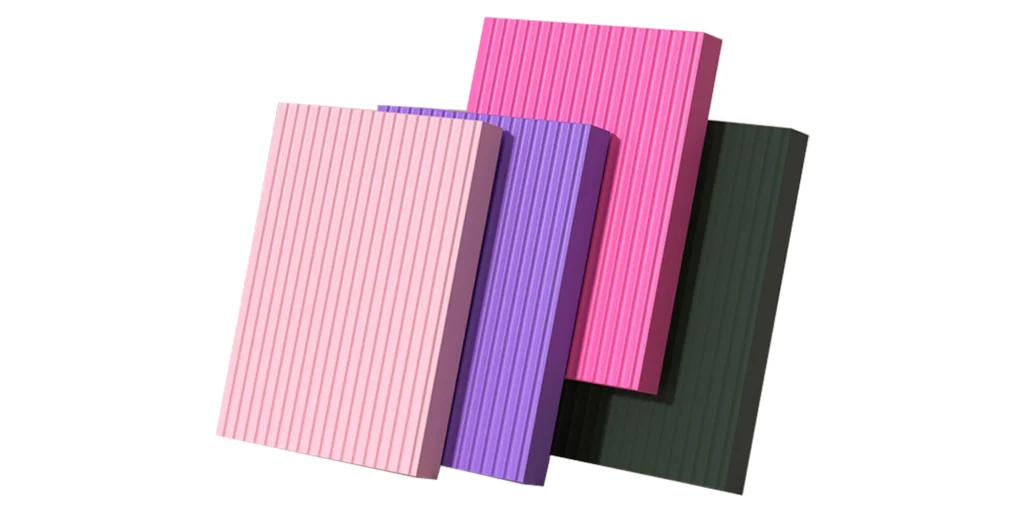

TPE foam is a type of foam made from thermoplastic elastomers. These are materials that combine the properties of rubber and plastic. Unlike traditional foam materials, TPE foam can be easily molded, is recyclable, and offers enhanced flexibility, making it a desirable choice for a variety of applications.

Key Features of TPE Foam:

- Flexible & Stretchable: Offers great flexibility, making it suitable for products that require stretching and bending.

- Lightweight: TPE foam is lighter than many other foam materials, making it a popular choice for applications where weight reduction is critical.

- Durable: Known for its resistance to wear and tear, TPE foam holds up well over time, even under constant pressure and exposure to the elements.

- Recyclable: Unlike some other foams, TPE foam can be recycled, making it an eco-friendly option in an increasingly sustainability-conscious market.

TPE Foam vs. EVA Foam: A Performance Comparison

EVA Foam

EVA foam is one of the most widely used foam materials, especially in industries like sports, footwear, and toys. It’s made from a polymer material known for its softness, flexibility, and shock-absorbing properties.

Key Features of EVA Foam:

- Soft & Cushiony: EVA foam is softer than many other types of foam, which makes it ideal for applications requiring cushioning.

- Shock Absorption: It has excellent shock absorption properties, making it popular for use in sports equipment and footwear.

- Water-Resistant: EVA foam is resistant to water, mold, and mildew, making it suitable for outdoor and aquatic environments.

- Non-Toxic: EVA foam is generally considered to be non-toxic, which makes it safe for use in products like children’s toys and medical items.

TPE Foam vs. EVA Foam: Key Differences

- Durability: TPE foam tends to be more durable than EVA foam, as it is more resistant to environmental factors such as temperature fluctuations and UV rays.

- Flexibility: While EVA foam is flexible, TPE foam offers even greater flexibility, especially in extreme temperature conditions, making it a better choice for applications that involve constant motion.

- Sustainability: TPE foam is more eco-friendly compared to EVA foam because it is easier to recycle, whereas EVA foam is more challenging to recycle and often ends up in landfills.

- Performance in Harsh Conditions: TPE foam outperforms EVA foam in terms of resistance to chemicals, oils, and extreme temperatures.

TPE Foam vs. PVC Foam: Durability and Versatility

PVC Foam

PVC foam is a lightweight and durable material widely used in industries ranging from construction to automotive. It is made from polyvinyl chloride and is known for its resistance to weathering and harsh chemicals.

Key Features of PVC Foam:

- Weather-Resistant: PVC foam has excellent resistance to the elements, making it ideal for outdoor applications.

- Chemical Resistance: It has great resistance to oils, solvents, and acids, which makes it popular in industrial applications.

- Lightweight: Despite its durability, PVC foam is lightweight, making it suitable for use in marine and construction industries where both strength and weight are critical.

TPE Foam vs. PVC Foam: Key Differences

- Environmental Impact: PVC foam is not as environmentally friendly as TPE foam, as it is difficult to recycle and can release harmful toxins during production and disposal.

- Flexibility: TPE foam is much more flexible and stretchable than PVC foam, which tends to be rigid and less versatile in applications requiring constant movement or bending.

- Durability: While PVC foam is durable and resistant to chemicals, TPE foam offers better long-term performance in high-stress applications, particularly where flexibility is essential.

TPE Foam vs. Other Popular Foam Materials

While TPE, EVA, and PVC are some of the most common foam materials, there are other options that could be compared depending on the specific application. Some notable mentions include polyurethane foam, polypropylene foam, and silicone foam.

- Polyurethane Foam: Known for its excellent cushioning properties, polyurethane foam is often used in furniture and bedding. However, it’s not as durable as TPE foam and tends to break down quicker under stress.

- Polypropylene Foam: Often used in packaging and insulation, polypropylene foam is lightweight and offers decent strength. However, it lacks the flexibility and sustainability that TPE foam provides.

- Silicone Foam: While silicone foam is highly heat-resistant, it is more expensive than TPE foam and is often overkill for applications that don’t require extreme heat resistance.

TPE Foam and Sustainability: A Growing Advantage

As global awareness around sustainability increases, the demand for eco-friendly materials has surged. TPE foam offers significant advantages in this regard. Unlike PVC and some types of EVA foam, TPE foam is recyclable and does not release harmful chemicals during its lifecycle. It’s also free from phthalates, BPA, and other harmful substances commonly found in plastics.

Why Sustainability Matters:

- Environmental Benefits: Using recyclable materials like TPE foam helps reduce landfill waste and conserves natural resources.

- Regulatory Compliance: Many regions around the world are tightening regulations on harmful chemicals in products. TPE foam, being free of such substances, allows manufacturers to meet these new standards more easily.

Applications of TPE Foam

Due to its versatility, TPE foam can be used in a wide range of applications. Some of the most common include:

- Sports Equipment: TPE foam is used in items like mats, padding, and protective gear due to its shock absorption and durability.

- Footwear: TPE foam is often used in insoles, providing both comfort and durability.

- Automotive: TPE foam is used in automotive components, including soundproofing, insulation, and sealing applications.

- Consumer Goods: From yoga mats to toys, TPE foam is a popular choice for a variety of consumer products, thanks to its flexibility and non-toxicity.

Selecting the right foam material for a given application depends on various factors such as durability, flexibility, cost, and sustainability. TPE foam stands out as a versatile and environmentally friendly option, especially when compared to materials like EVA, PVC, and polyurethane. Its combination of flexibility, strength, and recyclability positions it as a top choice for a wide range of industries, from sports and automotive to consumer goods and construction.

By understanding the differences between TPE foam and other popular foam materials, businesses can make more informed decisions and choose the best material for their needs, helping them stay competitive in an increasingly eco-conscious market.

By considering the benefits of TPE foam over other materials, manufacturers can enhance product offerings while meeting the growing demand for sustainable and durable solutions. Whether you’re in the automotive, sports, or consumer goods sector, TPE foam presents a future-proof solution that balances performance with environmental responsibility.

FAQ: TPE Foam vs. Other Foam Materials

1. What are the main advantages of TPE foam over EVA foam?

TPE foam offers superior durability, flexibility, and recyclability compared to EVA foam. It is more resistant to wear and environmental factors like UV rays and extreme temperatures, making it ideal for high-performance applications.

2. Is TPE foam environmentally friendly?

Yes, TPE foam is highly sustainable. It is recyclable and free from harmful substances like phthalates, BPA, and PVC, making it a safer and more eco-friendly option compared to other foam materials.

3. How does TPE foam compare to PVC foam in terms of flexibility?

TPE foam is more flexible and stretchable than PVC foam, which tends to be more rigid. This makes TPE foam a better choice for applications requiring constant bending or stretching.

4. Can TPE foam be used in outdoor applications?

Yes, TPE foam is suitable for outdoor use due to its durability, resistance to UV rays, and weatherability. It is a great alternative for outdoor gear, mats, and protective padding.

5. Is TPE foam more expensive than other foam materials?

While TPE foam may be slightly more expensive than EVA or PVC foam, its long-lasting durability and recyclability can provide greater long-term value. Additionally, the increasing demand for sustainable products makes TPE foam a competitive choice in the market.

#TPEFoam #FoamMaterials #SustainableFoam #EVAfoam #PVCfoam #EcoFriendlyProducts #FoamComparison #RecyclableFoam #DurableFoam #FlexibleFoam #GreenManufacturing #FoamApplications #EcoFriendlySolutions #SustainableMaterials

WELLE Trade has over 20 years of experience in the production and processing of PE/EVA/TPE foams, so you may want to consult with them if you have any sourcing needs.