Thermoplastic elastomer (TPE) foam is a high-performance material that is increasingly used in various industries, especially in automotive and industrial applications. While TPE foam is well-known for its use in products like mats, its potential goes far beyond that. This versatile material plays a crucial role in automotive padding, soundproofing, shock absorption, and a host of other applications, offering significant benefits such as durability, flexibility, and environmental friendliness.

In this article, we’ll explore the diverse uses of TPE foam in automotive and industrial sectors, highlighting its unique properties and advantages in each field.

What is TPE Foam?

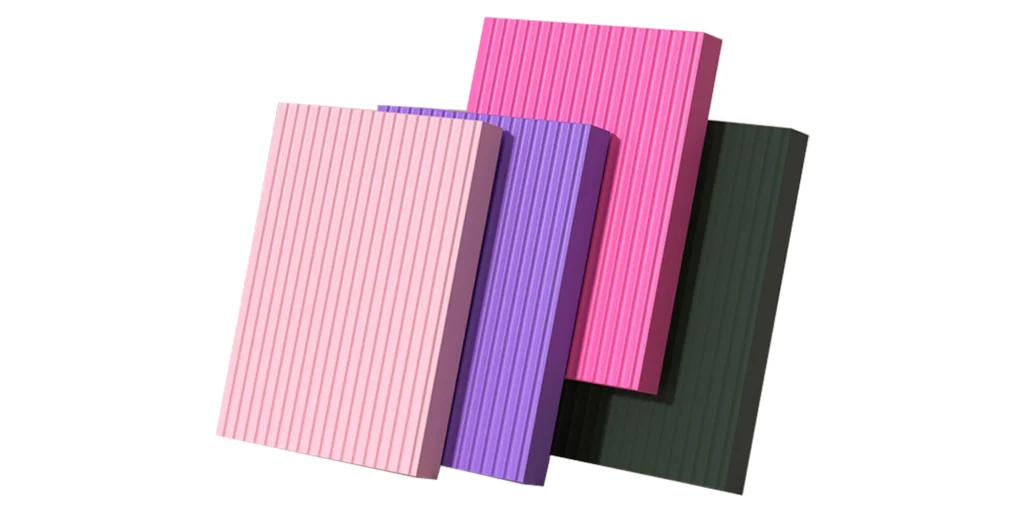

TPE foam is a lightweight, flexible material made from thermoplastic elastomers, which combine the best properties of both rubber and plastic. This makes TPE foam a highly versatile solution, offering elasticity, flexibility, and a high degree of durability, along with excellent chemical resistance. Additionally, TPE foam can be easily molded into various shapes and sizes, making it ideal for a wide range of industrial applications.

1. TPE Foam in Automotive Padding

One of the most important uses of TPE foam in the automotive industry is in the creation of automotive padding. TPE foam’s excellent shock-absorbing properties make it an ideal choice for padding used in car seats, headrests, armrests, and other interior components. Here are a few key reasons why TPE foam is a preferred material for automotive padding:

- Comfort: TPE foam provides a high level of comfort for passengers by offering soft, yet supportive cushioning. Its elastic nature allows it to conform to body contours, which can enhance the overall driving experience.

- Impact Resistance: TPE foam’s ability to absorb shocks and impacts makes it suitable for use in areas that require additional protection, such as in side impact zones or interior padding for collision mitigation.

- Durability: The material’s resistance to wear and tear, as well as its ability to withstand temperature fluctuations, ensures long-lasting performance in vehicles. This makes TPE foam an excellent investment for automotive manufacturers seeking durable and low-maintenance solutions.

- Customization: TPE foam can be easily customized to meet the specific needs of the automotive industry, whether it’s for different levels of density, color, or shape.

2. TPE Foam in Soundproofing Applications

TPE foam is also widely used for soundproofing applications, particularly in automotive and industrial environments where noise reduction is crucial. In automotive applications, for instance, TPE foam is used in the construction of door panels, floor mats, and roof linings, helping to reduce road noise and improve the overall acoustic environment inside the vehicle.

In industrial settings, TPE foam is used in machinery enclosures, soundproof barriers, and equipment linings to minimize noise levels and prevent the transmission of unwanted sounds. Key benefits of TPE foam for soundproofing include:

- Noise Absorption: TPE foam’s unique structure allows it to absorb sound waves, reducing noise transmission between different areas.

- Vibration Dampening: The material also effectively dampens vibrations, making it ideal for use in industrial machinery, vehicles, and appliances.

- Lightweight and Efficient: Despite its soundproofing capabilities, TPE foam is lightweight, which is crucial for automotive and industrial applications where weight reduction is a priority.

3. TPE Foam for Shock Absorption

In both automotive and industrial sectors, shock absorption is critical for protecting sensitive components and enhancing safety. TPE foam excels in this area due to its remarkable ability to absorb and dissipate energy. This makes it an essential material in products ranging from bumpers and crash pads in cars to vibration-damping components in industrial machines.

- Automotive Shock Absorption: In vehicles, TPE foam is used in bumpers, door panels, and interior cushioning systems. It helps to reduce the impact during a collision, improving safety for passengers and minimizing vehicle damage. Additionally, TPE foam is used in suspension systems to dampen vibrations and ensure a smooth ride.

- Industrial Shock Absorption: In industrial environments, TPE foam is used to protect machinery and equipment from excessive vibration and impact. It is commonly found in conveyor systems, heavy-duty machinery, and packaging materials, where shock resistance is crucial for operational efficiency and longevity.

4. Environmental Benefits of TPE Foam

One of the key advantages of TPE foam over other materials is its environmental friendliness. Unlike traditional foam materials, such as polyurethane, TPE foam is fully recyclable, making it a sustainable option for automotive and industrial manufacturers. This characteristic is especially valuable as industries increasingly prioritize green manufacturing practices and seek ways to reduce their environmental impact.

- Recyclability: TPE foam can be melted down and reused in manufacturing new products, helping to reduce waste and promote a circular economy.

- Non-toxic: TPE foam does not release harmful chemicals or pollutants during production or use, making it a safer alternative for both workers and end-users.

5. TPE Foam in Industrial Seals and Gaskets

Beyond automotive and soundproofing applications, TPE foam is widely used in industrial sealing solutions. It is commonly found in seals and gaskets for machinery, electrical components, and appliances. TPE foam’s ability to maintain a reliable seal under various conditions, including exposure to moisture, heat, and chemicals, makes it an ideal material for these applications.

- Sealing Efficiency: TPE foam’s resilience to environmental factors ensures that seals and gaskets provide long-lasting protection against leaks and contamination.

- Versatility: Whether used in sealing windows, doors, or pipes, TPE foam can be tailored to suit the specific requirements of different industries.

TPE foam is an incredibly versatile material with diverse applications in both automotive and industrial sectors. Its properties of flexibility, durability, shock absorption, soundproofing, and recyclability make it a highly attractive option for manufacturers across industries. Whether it’s in automotive padding, soundproofing, shock absorption, or sealing applications, TPE foam offers practical and cost-effective solutions that can enhance product performance and sustainability.

As the demand for advanced materials continues to rise, TPE foam is poised to play an even larger role in automotive and industrial innovations, providing manufacturers with a reliable and environmentally friendly material for a wide range of applications. If you’re in the market for high-quality TPE foam solutions, be sure to consider its full potential beyond mats and explore its many benefits across different industries.

FAQ: TPE Foam in Automotive and Industrial Applications

1. What is TPE foam, and what are its primary uses?

TPE foam is a thermoplastic elastomer material that combines the best features of rubber and plastic. It is widely used in automotive padding, soundproofing, shock absorption, and sealing applications due to its durability, flexibility, and recyclability.

2. How does TPE foam enhance automotive padding?

TPE foam improves comfort, impact resistance, and durability in automotive padding. It provides soft, supportive cushioning for car seats, headrests, and armrests while also offering protection against impacts in side collision zones.

3. Can TPE foam be used for soundproofing in vehicles?

Yes, TPE foam is highly effective for soundproofing applications in vehicles. It absorbs road noise and reduces vibrations, making the interior of the vehicle quieter and more comfortable for passengers.

4. What makes TPE foam a good choice for shock absorption?

TPE foam excels in shock absorption due to its ability to dissipate impact energy. This makes it ideal for use in automotive bumpers, crash pads, and industrial machinery to minimize damage from impacts and vibrations.

5. Is TPE foam environmentally friendly?

Yes, TPE foam is fully recyclable and non-toxic, making it an environmentally friendly alternative to traditional foams like polyurethane. It contributes to a circular economy by being reusable in new products, reducing waste in manufacturing processes.

#TPEFoam #AutomotivePadding #Soundproofing #ShockAbsorption #IndustrialApplications #EcoFriendlyMaterials #RecyclableFoam #SustainableManufacturing #CarInteriorDesign #VibrationDamping #GreenManufacturing

WELLE Trade has over 20 years of experience in the production and processing of PE/EVA/TPE foams, so you may want to consult with them if you have any sourcing needs.