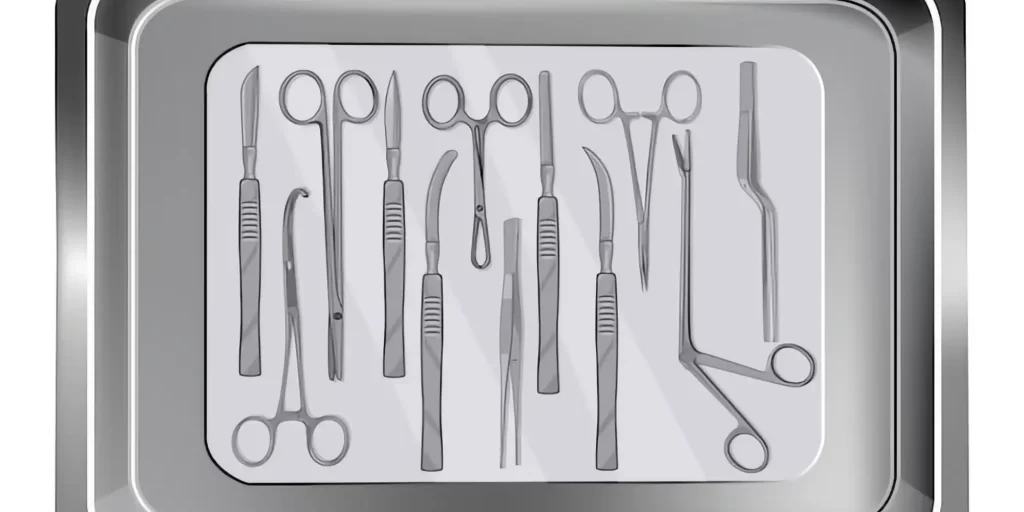

In the highly specialized and critical field of medical surgery, the safety and sterility of surgical instruments are of utmost importance. Ethylene-Vinyl Acetate (EVA) foam has emerged as a key material in the packaging of these delicate instruments. Known for its protective and durable properties, EVA foam plays a crucial role in maintaining the integrity and readiness of surgical tools. This article explores the benefits of EVA foam in surgical instruments packaging and answers frequently asked questions about its application in this vital area.

The Benefits of EVA Foam in Surgical Instruments Packaging

EVA foam brings several key advantages to the packaging of surgical instruments:

1. Superior Protection:

EVA foam provides excellent cushioning and shock absorption, protecting delicate instruments from damage during transportation and handling.

2. Customizable Fit:

Its ability to be molded into various shapes allows for a customized fit for different types of surgical instruments, ensuring each tool is securely held in place.

3. Durability and Longevity:

EVA foam is resistant to wear and tear, chemicals, and moisture, making it an ideal material for reusable packaging that maintains its protective qualities over time.

4. Sterility Maintenance:

Its non-porous surface prevents the accumulation of contaminants, aiding in the maintenance of sterility of the instruments.

5. Lightweight:

EVA foam is incredibly lightweight, adding minimal weight to the overall package, which is essential for ease of transport and handling.

6. Aesthetic and Professional Appearance:

EVA foam can be customized in terms of color and texture, providing a professional and clean appearance suitable for medical settings.

Applications of EVA Foam in Surgical Instruments Packaging

Standard Surgical Kits:

EVA foam is used in the packaging of standard surgical kits, providing organization and protection for a variety of instruments.

Specialized Surgical Sets:

For specialized surgeries, custom EVA foam inserts are created to fit specific tools, ensuring each instrument is securely stored.

Portable Surgical Packs:

In portable surgical packs used in field hospitals or emergency situations, EVA foam ensures instruments remain sterile and undamaged.

Diagnostic Equipment:

EVA foam is also used in the packaging of delicate diagnostic equipment, providing protection against physical and environmental factors.

Advancing Medical Safety with EVA Foam

The integration of EVA foam into surgical instruments packaging represents a significant advancement in medical safety, focusing on the protection, sterility, and longevity of critical tools.

FAQs About EVA Foam in Surgical Instruments Packaging

Q: How does EVA foam protect surgical instruments?

A: EVA foam cushions and absorbs shocks, protecting instruments from damage during transportation and handling.

Q: Can EVA foam packaging be customized for different surgical instruments?

A: Yes, EVA foam can be molded into various shapes and sizes, allowing for customization to fit specific surgical instruments.

Q: Is EVA foam packaging durable for long-term use?

A: EVA foam is known for its durability and resistance to wear and tear, making it suitable for long-term and repeated use.

Q: How does EVA foam contribute to maintaining the sterility of surgical instruments?

A: The non-porous surface of EVA foam prevents the accumulation of contaminants, aiding in maintaining the sterility of the instruments.

Q: Is EVA foam environmentally friendly?

A: The environmental impact of EVA foam depends on the manufacturing process. However, there is a growing focus on making EVA foam production more sustainable.

In conclusion, EVA foam has become an essential component in the packaging of surgical instruments, providing enhanced protection, sterility, and durability. Its combination of shock absorption, customizable fit, and lightweight design makes it an ideal choice for medical packaging solutions. As the focus on medical safety and efficiency continues to grow, EVA foam-enhanced packaging for surgical instruments is set to remain a vital part of the healthcare industry, offering effective solutions for the safe handling and transportation of critical medical tools.