EVA (Ethylene Vinyl Acetate) foam dowels are rapidly becoming essential tools in the world of model making and prototyping. With their unique properties, EVA foam dowels provide advantages that traditional materials cannot match. This article will explore the role of EVA foam dowels in model making and prototyping, highlighting their benefits, applications, and why they are a valuable asset for both hobbyists and professionals.

What Are EVA Foam Dowels?

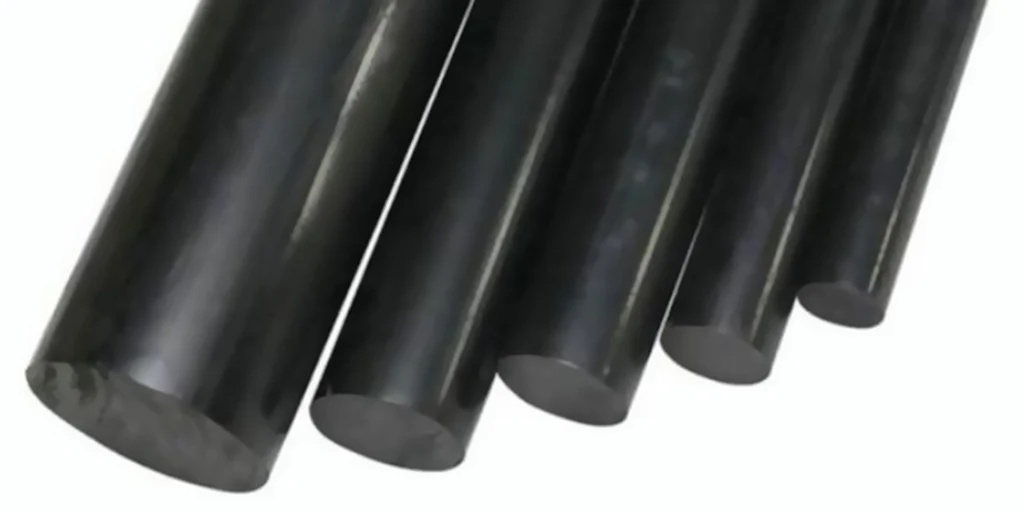

EVA foam is a lightweight, flexible material known for its durability and shock-absorbent properties. Dowels made from EVA foam are cylindrical rods that can be used in various applications, including construction, model making, and prototyping. These dowels come in various sizes and thicknesses, making them versatile for different projects. Their smooth surface allows for easy cutting, shaping, and finishing, which is crucial in achieving precise designs.

Advantages of Using EVA Foam Dowels

1. Lightweight and Easy to Handle

One of the primary benefits of EVA foam dowels is their lightweight nature. This characteristic makes them easy to handle and transport, allowing model makers to work on projects without the burden of heavy materials. This ease of use is especially beneficial in prototyping, where multiple iterations are often required.

2. Flexibility and Customization

EVA foam is known for its flexibility, which allows dowels to be bent or shaped to fit specific design needs. This property is essential for model makers who require precise angles and curves in their projects. Additionally, EVA foam dowels can be easily cut, glued, and painted, enabling custom designs that align with creative visions.

3. Durable and Impact-Resistant

EVA foam is resistant to wear and tear, making it ideal for models and prototypes that need to withstand handling and transport. The impact-resistant nature of EVA foam dowels ensures that they maintain their structural integrity over time, providing longevity for projects that require durability.

4. Cost-Effective

Compared to traditional materials like wood or metal, EVA foam dowels are more affordable. This cost-effectiveness makes them an attractive option for hobbyists and professionals alike. Furthermore, the ease of use and minimal waste during cutting and shaping help keep project costs down.

Applications in Model Making

EVA foam dowels are widely used in various aspects of model making, including:

1. Structural Support

In model building, EVA foam dowels can provide crucial structural support. Whether creating architectural models or detailed dioramas, these dowels can be used as internal supports, ensuring stability and strength in the final product.

2. Creating Frameworks

Model makers often need to construct frameworks for their designs. EVA foam dowels can serve as a framework’s backbone, allowing for easy assembly and modification. Their lightweight nature makes them an excellent choice for supporting larger models without adding excessive weight.

3. Functional Components

In addition to structural support, EVA foam dowels can be used as functional components in models. For example, they can be utilized in moving parts or as connections between different sections of a model, contributing to the overall functionality and design.

Prototyping Benefits

The use of EVA foam dowels in prototyping offers several advantages:

1. Rapid Iteration

In the prototyping phase, speed is often critical. EVA foam dowels can be quickly cut and shaped to create multiple prototypes in a short amount of time. This rapid iteration allows designers to test ideas efficiently and refine their concepts without being bogged down by lengthy production processes.

2. Enhanced Design Flexibility

Prototyping often requires adjustments based on testing and feedback. EVA foam dowels can be modified easily, enabling designers to make changes on the fly. This adaptability ensures that prototypes can evolve rapidly in response to new insights or requirements.

3. Cost-Effective Prototyping

Budget constraints are common in prototyping. Using EVA foam dowels minimizes costs while allowing designers to create functional prototypes without compromising quality. Their affordability makes them an excellent choice for startups and smaller projects.

EVA foam dowels have emerged as invaluable tools in model making and prototyping. Their lightweight, flexible, and durable properties make them suitable for a variety of applications, from providing structural support to creating functional components. As the demand for innovative designs continues to grow, incorporating EVA foam dowels into model making and prototyping processes can enhance efficiency, creativity, and cost-effectiveness. Whether you are a hobbyist or a professional, considering EVA foam dowels for your next project could lead to significant improvements in your design and prototyping endeavors.

By understanding the role and benefits of EVA foam dowels, you can harness their potential to create exceptional models and prototypes that stand out in both form and function.

FAQ

1. What are EVA foam dowels used for in model making?

EVA foam dowels are primarily used for structural support, creating frameworks, and functional components in model making. Their lightweight and durable nature makes them ideal for various applications.

2. How do EVA foam dowels compare to traditional materials?

EVA foam dowels are lighter and more flexible than traditional materials like wood or metal. They are also cost-effective, easy to handle, and resistant to wear and tear, making them suitable for both hobbyists and professionals.

3. Can EVA foam dowels be painted or glued?

Yes, EVA foam dowels can be easily painted, glued, and modified to fit specific design needs. This customization allows model makers to achieve precise designs and enhance the aesthetics of their projects.

4. Are EVA foam dowels suitable for prototyping?

Absolutely! EVA foam dowels are ideal for prototyping due to their ease of use, rapid iteration capabilities, and cost-effectiveness. They allow designers to create functional prototypes quickly and efficiently.

5. Where can I purchase EVA foam dowels?

EVA foam dowels can be found at craft stores, specialty model making shops, and online retailers. Ensure to check for various sizes and thicknesses to suit your specific project requirements.

#EVAfoam #ModelMaking #Prototyping #Crafting #DesignTools #DIYProjects #Innovation #CreativeDesign #Hobbyist #ArtisanCrafts

WELLE Trade has over 20 years of experience in the production and processing of PE/EVA/TPE foams, so you may want to consult with them if you have any sourcing needs.