Thermoplastic Elastomer (TPE) foam has gained considerable attention across various industries due to its unique combination of flexibility, durability, and environmental benefits. With advancements in material science and growing demand for sustainable products, the future of TPE foam looks promising. This article explores the trends shaping the TPE foam market, potential new applications, growth projections, and innovations that are on the horizon.

What is TPE Foam?

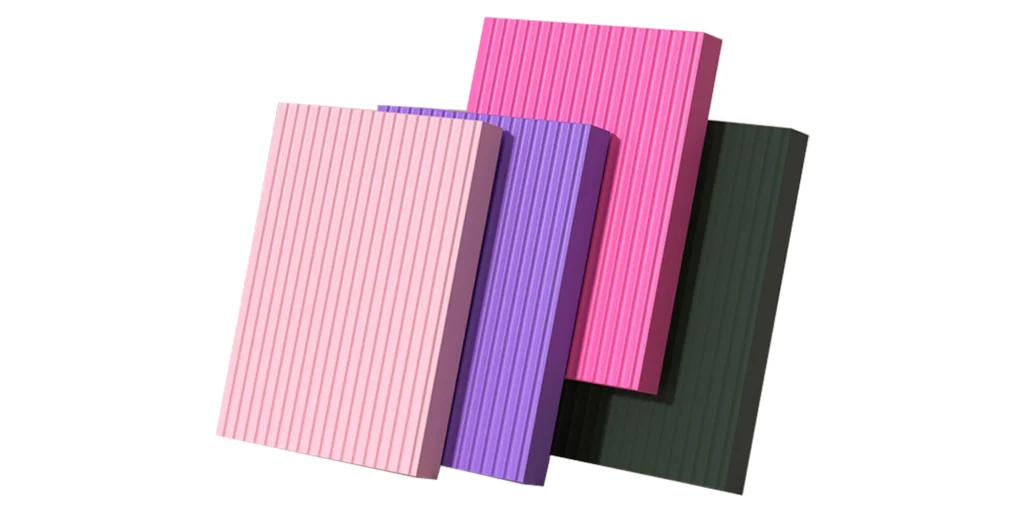

TPE foam is a versatile material that combines the properties of rubber with the processing advantages of thermoplastics. This material is known for its flexibility, elasticity, and light weight, making it suitable for a wide range of applications. TPE foam can be molded into various shapes, offering excellent insulation, cushioning, and shock-absorbing qualities. Additionally, it is highly resistant to wear, UV light, and chemicals, which contributes to its long-lasting performance in demanding environments.

Key Trends Driving the TPE Foam Market

1. Sustainability and Eco-Friendly Materials

Sustainability has become a driving force in the development of materials across industries, and TPE foam is no exception. Manufacturers are increasingly focused on creating eco-friendly products that are recyclable, biodegradable, and free from harmful chemicals. As environmental concerns continue to rise, the demand for TPE foam, which can be recycled and reused, is expected to grow.

Furthermore, the shift towards reducing carbon footprints in manufacturing processes is propelling the development of green TPE foam. Innovations in the production process are making it possible to use renewable resources in the manufacturing of TPE foam products, which aligns with the broader global trend of sustainability.

2. Increasing Demand for Lightweight and Durable Materials

Across industries such as automotive, construction, and consumer goods, there is a growing demand for materials that are both lightweight and durable. TPE foam offers an ideal solution due to its ability to reduce weight without compromising strength or functionality. The automotive industry, in particular, is adopting TPE foam to reduce vehicle weight, which contributes to better fuel efficiency and reduced emissions.

Similarly, in the construction sector, TPE foam is being used for insulation and cushioning applications, where its lightweight nature helps in reducing the overall weight of building materials, making construction more efficient and cost-effective.

3. Expanding Applications in the Automotive Industry

The automotive sector is one of the largest consumers of TPE foam, and its usage is set to expand even further. TPE foam is used in car interiors for seating, sound insulation, and vibration dampening. It is also being utilized for exterior parts, including bumpers and seals, due to its impact resistance and long-term durability.

With the growing demand for electric vehicles (EVs), TPE foam is gaining popularity as an alternative material for lightweight components. The trend toward electric vehicles, which require lighter and more energy-efficient materials, is expected to boost the adoption of TPE foam in automotive applications.

4. Technological Innovations in TPE Foam

Ongoing advancements in material science and production technologies are paving the way for new innovations in TPE foam. Researchers are exploring ways to enhance the performance of TPE foam by incorporating additives that improve its thermal stability, fire resistance, and mechanical properties. Furthermore, the development of new production methods, such as 3D printing, is enabling the creation of highly customized TPE foam products for specific applications.

These innovations are not only making TPE foam more versatile but are also expanding its range of potential uses in industries that require highly specialized materials.

Potential New Uses for TPE Foam

1. Wearable Technology and Health Devices

As the wearable technology market continues to grow, TPE foam is poised to become a key material in the development of health monitoring devices, fitness trackers, and other wearable products. The flexibility and comfort of TPE foam make it an ideal choice for wearable straps, while its durability ensures that these products can withstand regular wear and tear.

Additionally, TPE foam’s hypoallergenic and skin-friendly properties make it suitable for direct contact with the skin, making it a popular material for medical and health-related applications, such as orthopedic supports and ergonomic cushioning.

2. Packaging Industry

The demand for sustainable packaging solutions is on the rise, and TPE foam’s unique properties make it an attractive option for the packaging industry. TPE foam can be used for protective packaging to safeguard fragile items during transit, while its recyclability makes it an eco-friendly alternative to traditional plastic foam packaging. With the growing focus on reducing plastic waste, the use of TPE foam in packaging is expected to expand rapidly.

3. Consumer Electronics

TPE foam is also finding new applications in the consumer electronics industry. It is being used for the production of shock-absorbing materials for smartphones, tablets, and other portable devices. The lightweight nature of TPE foam, combined with its protective properties, helps to safeguard electronic devices from damage caused by drops or impacts.

As consumer electronics continue to shrink in size and increase in functionality, the demand for lightweight, durable, and flexible materials like TPE foam is expected to rise.

Market Growth and Projections

The global market for TPE foam is expected to experience significant growth in the coming years. According to industry analysts, the demand for TPE foam is forecasted to grow at a compound annual growth rate (CAGR) of over 6% between 2024 and 2030. Several factors are contributing to this growth, including the increasing adoption of TPE foam in various industries, innovations in material science, and the growing trend toward sustainable and eco-friendly products.

Asia-Pacific is anticipated to be the largest market for TPE foam, driven by the rapid industrialization in countries like China, India, and Japan. The automotive and construction sectors in this region are expanding rapidly, creating a robust demand for TPE foam.

North America and Europe are also expected to see strong growth, particularly in the automotive and healthcare sectors, where there is a push for lightweight, durable, and environmentally friendly materials.

The future of TPE foam looks bright, with emerging trends and innovations driving its growth across a wide range of industries. From sustainability to technological advancements, TPE foam is evolving to meet the needs of a changing market. With new applications in automotive, consumer electronics, healthcare, and packaging, the potential for TPE foam is vast. As industries continue to prioritize eco-friendly, lightweight, and durable materials, TPE foam will undoubtedly play a key role in shaping the future of manufacturing and product design.

By staying ahead of these trends and embracing new technologies, manufacturers can position themselves for success in the expanding TPE foam market. The future is full of opportunities for TPE foam to become an integral part of the global industrial landscape.

FAQ: The Future of TPE Foam

1. What is TPE foam and why is it important?

TPE foam is a versatile material that combines the properties of rubber and thermoplastics. It is lightweight, flexible, durable, and eco-friendly, making it an ideal choice for a wide range of applications, including automotive, consumer goods, and packaging.

2. What industries are driving the growth of TPE foam?

The automotive, healthcare, packaging, consumer electronics, and construction industries are among the main sectors driving the demand for TPE foam due to its lightweight, durable, and sustainable properties.

3. How is TPE foam contributing to sustainability?

TPE foam is recyclable, biodegradable, and often produced from renewable resources, making it an environmentally friendly material choice. It helps reduce the reliance on single-use plastics and offers a more sustainable alternative for various applications.

4. What are the potential new applications for TPE foam in the future?

TPE foam is expected to see growth in wearable technology, health devices, consumer electronics, and packaging. Its flexible, shock-absorbing properties make it suitable for a wide range of new uses.

5. What is the projected market growth for TPE foam?

The global market for TPE foam is projected to grow at a compound annual growth rate (CAGR) of over 6% between 2024 and 2030, driven by advancements in material science and the increasing demand for eco-friendly products.

#TPEFoam #SustainableMaterials #FutureOfFoam #EcoFriendlyProducts #MaterialInnovation #AutomotiveTrends #PackagingSolutions #ConsumerElectronics #WearableTechnology #GreenManufacturing #ThermoplasticElastomers #LightweightMaterials #MarketGrowth #TechInnovation #SustainabilityInManufacturing #FoamIndustry

WELLE Trade has over 20 years of experience in the production and processing of PE/EVA/TPE foams, so you may want to consult with them if you have any sourcing needs.