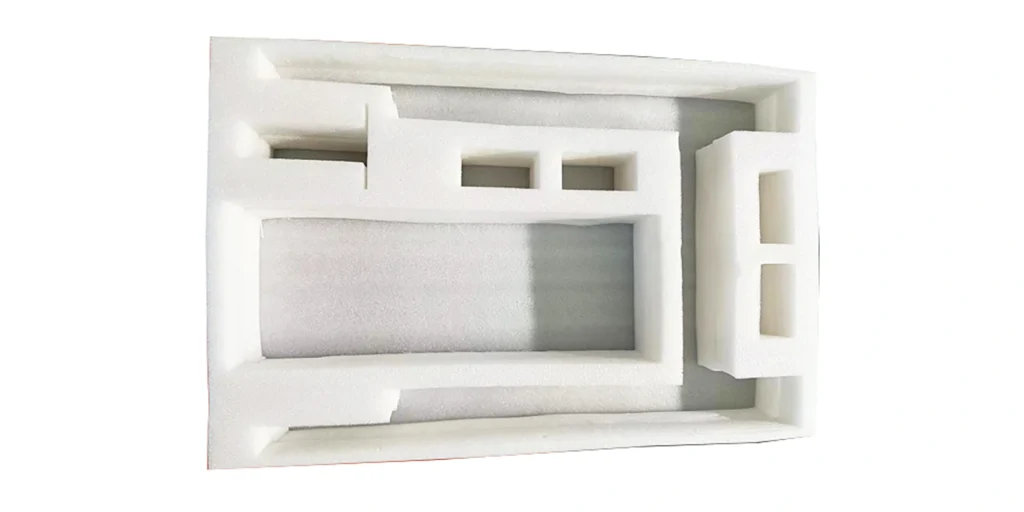

PE Foam Recyclable Material: Revolutionizing Sustainable Packaging Solutions

Abstract PE Foam (polyethylene foam), renowned for its lightweight and superior cushioning properties, has long been a staple in protective packaging for electronics, furniture, medical equipment, and more. As global environmental awareness grows, its recyclability and low-carbon production processes are now at the forefront of industry innovation. This article provides an in-depth analysis of PE […]

PE Foam Recyclable Material: Revolutionizing Sustainable Packaging Solutions Read More »