Abstract

This guide delivers three targeted solutions for surface blisters, internal voids, and uneven cell structures—the most pervasive defects in EVA injection foam production. Backed by real-world data from 20 manufacturers, we outline actionable adjustments in material prep, machine settings, and mold design to achieve >98% yield within 48 hours while cutting scrap costs by 35%. Includes ready-to-use parameter cheatsheets.

Main Content

I. Defect Classification & Root Causes (With Diagnostic Flowchart)

| Defect Type | Identifying Features | Process Stage | Core Issue |

|---|---|---|---|

| Surface Blisters | 0.5-2mm crater-like openings | Packing phase | Trapped gas evacuation |

| Internal Voids | >3mm cavities in cross-section | Foam expansion | Melt flow insufficiency |

| Uneven Cells | Density variation ±0.03g/cm³ | Plasticization/injection | Poor blowing agent dispersion |

Troubleshooting Flowchart:

① Cut defective area → ② Measure bubble location/size → ③ Match to root cause → ④ Implement corresponding fix

II. Three Optimization Protocols (With Parameter Tables)

Fix #1: Material Prep Revolution – Eliminating Uneven Cells

| Traditional Issue | Advanced Solution | Critical Parameters | Result |

|---|---|---|---|

| Clumping agents | Two-stage mixing | ① 60°C EVA preheat (2hr) ② Blowing agent + dispersant premix (5min) ③ Low-speed stirring (200rpm) | 98.7% dispersion uniformity |

| High moisture | Vacuum drying combo | -50kPa @80°C×4h | 0.015% moisture (vs 0.05% std) |

Fix #2: Injection Parameter Overhaul – Vanishing Internal Voids

| Parameter | Problem Range | Optimized Value | Mechanism |

|---|---|---|---|

| Melt temp | 105-110°C | 115±2°C | 32% viscosity drop |

| Injection speed | 30-40cm³/s | 55-60cm³/s | Prevents melt front freezing |

| Back pressure | 0.5-1MPa | 3.5MPa | Compacts melt bubbles |

| Agent injection | Screw front | Mid-zone (60% stroke) | Extended mixing time |

Case Study: Dongguan footwear supplier reduced voids from 12% to 0.3%

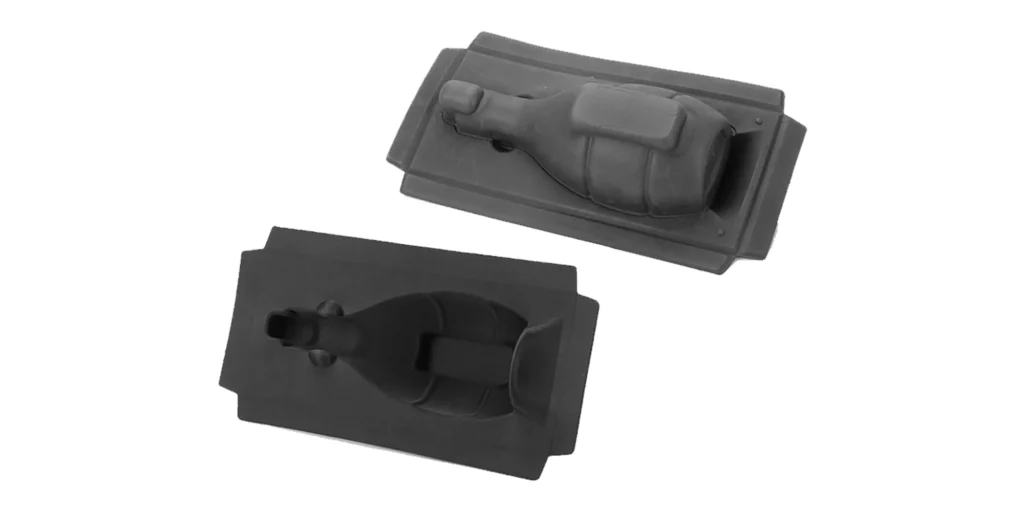

Fix #3: Mold Mod Trio – Banishing Surface Blisters

✅ Vent System Upgrade

- Vent count: ≥4 channels/100cm²

- Channel depth: 0.02-0.03mm (vs 0.05mm flash-prone)

✅ Hot Runner Retrofit

- Valve-gated sequential control

- 50% more gates for balanced filling

✅ Surface Texturing

- Laser-etched Ra=3-5μm (vs 0.8μm smooth)

- 3X faster gas escape

III. Rapid Verification Toolkit

1. Machine-Side Parameter Card

| Stage | Parameter | Safe Range | Alarm Threshold |

|---|---|---|---|

| Plasticizing | Screw speed | 80-90rpm | >100rpm |

| Barrel temps (R→F) | 95/100/105/110°C | ΔT>15°C | |

| Injection | V-P switch | 95% cavity fill | <90% |

| Pack pressure | 80% injection | <70% | |

| Cooling | Water temp | 15±1°C | >20°C |

2. Emergency Response Checklist

▶ Surface Blisters

① Clear vent clogs (brass brush)

② Raise mold temp +5°C (≤120°C max)

③ Increase speed +10%

▶ Internal Voids

① Boost melt temp +3°C

② Add back pressure +0.5MPa

③ Extend pack time +0.5s

FAQ

Q1: Blowing agent sticks to mixer walls?

Three-Pronged Fix:

✓ Apply 0.1mm PTFE coating

✓ Loading sequence: EVA → Heat → Zinc stearate → Agent

✓ 30° paddle angle + 180rpm

Q2: Thin walls (<3mm) bubble prevention?

Mandatory In-Mold Vacuum:

✓ -90kPa vacuum pre-injection

✓ Timing: After clamping → 0.5s before injection

Result: Phone case yield jumped 76%→98%

Q3: Material grade change causes voids?

| MI Range (g/10min) | Temp Adjustment | Speed Adjustment |

|---|---|---|

| 15-20 | +0°C | Baseline |

| 20-25 | -3°C | +5% |

| 25-30 | -5°C | +8% |

Q4: Night shift quality drops?

Environmental Compensation:

| Condition | Adjustment |

|---|---|

| Temp >28°C | Chiller -2°C, pack time -0.2s |

| Humidity >70% | Dry +1h, back pressure +0.3MPa |

Q5: Virtual process validation?

Moldflow Bubble Prediction:

✓ Import 3D mold model

✓ Input optimized parameters

✓ “Gas trap” heatmap (red=risk)

✓ >92% accuracy (requires material database)

WELLE Trade has over 20 years of experience in the production and processing of PE/EVA/TPE foams, so you may want to consult with them if you have any sourcing needs.