Abstract

Polyethylene (PE) foam sheets, renowned for their lightweight properties, superior cushioning, and corrosion resistance, are extensively utilized in packaging, construction, automotive manufacturing, and sports equipment industries. The customization of profiled (non-standard shaped) products represents a pivotal extension of PE foam’s functional applications. This article delves into the core techniques, technical challenges, and industry-specific applications of PE foam profiling, supplemented by an FAQ section addressing common inquiries, facilitating optimized material selection and production decision-making for enterprises.

Technical Analysis of PE Foam Profiling

Key Processing Techniques

Precision Cutting: Employs CNC routing, laser engraving, or waterjet cutting technologies to achieve high-accuracy shaping of intricate geometries.

Thermoforming: Utilizes heated molds to press and conform PE foam into curved profiles, ideal for automotive interiors and other contoured applications.

Surface Treatment: Enhances abrasion resistance, water repellency, and branding through lamination, coating, or printing.

Technical Challenges and Solutions

Elastic Recovery Control: PE foam’s high elasticity may cause post-cutting deformation, mitigated via cryogenic cooling or custom tooling parameter optimization.

Precision Alignment for Complex Assemblies: Incorporates 3D scanning and reverse engineering to ensure seamless multi-component integration.

Environmental Compliance: Adheres to RoHS/REACH standards with low-VOC materials and processes.

Industry Applications

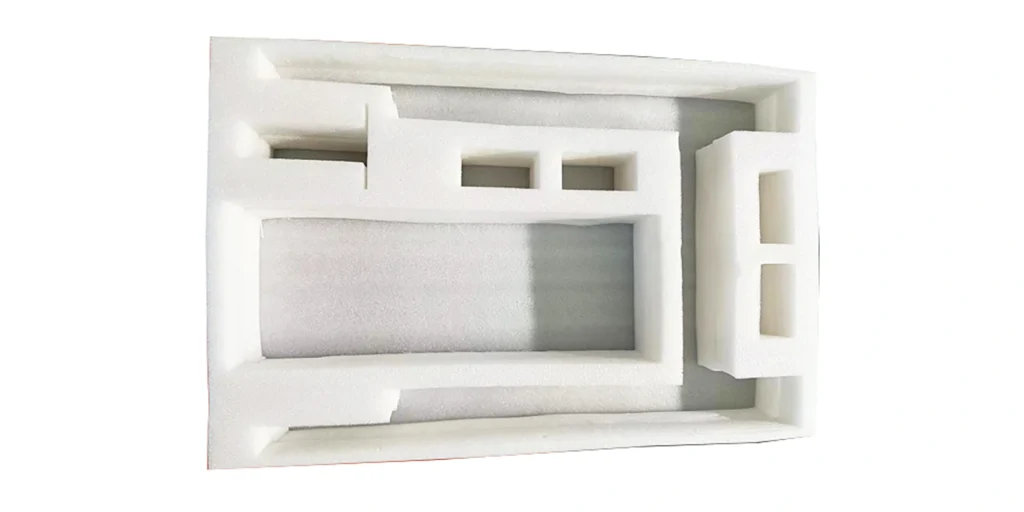

Electronics Packaging: Custom shock-absorbing liners minimize transit damage.

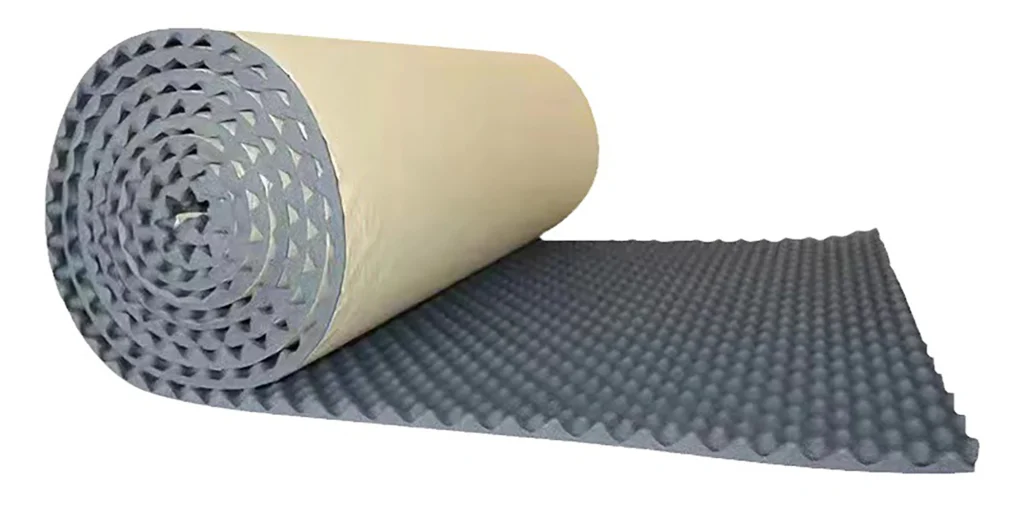

Acoustic Insulation: Profiled interlocking designs optimize sound attenuation in construction.

Sports Protective Gear: Ergonomic shaping improves wearability and impact absorption.

FAQ: Common Queries on PE Foam Profiling

Q1: How to select foam density?

A: Low-density (20-30kg/m³) suits lightweight packaging, while high-density (100-200kg/m³) is optimal for load-bearing components. Conduct load testing for precise specifications.

Q2: Minimum thickness and tolerances achievable?

A: Standard profiling accommodates 1–100mm thickness with ±0.5mm tolerances (equipment-dependent). Laser cutting is recommended for ultrathin requirements.

Q3: Lead time for custom production?

A: 3–5 days for simple designs; 2–4 weeks for complex mold development. Pre-production design validation is advised.

Q4: Resolving edge melting/burring?

A: Optimize cutting speed/power or employ cryogenic waterjet cutting with post-process polishing.

Q5: Advantages over EVA/PU alternatives?

A: Superior hydrophobicity (closed-cell structure), 30% cost efficiency, and full recyclability.

Industry Outlook

Driven by “plastic substitution for wood” policies and EV lightweighting demands, PE foam profiling is advancing toward precision, sustainability, and smart manufacturing. Strategic adoption of digital design tools (e.g., AI-generated structural solutions) and automated production lines will be critical for market leadership in niche segments.

WELLE Trade has over 20 years of experience in the production and processing of PE/EVA/TPE foams, so you may want to consult with them if you have any sourcing needs.