Abstract

Polyethylene Foam Sheets (PE Foam Sheets) have emerged as a cornerstone material in the realm of shock absorption and cushioning products, owing to their lightweight nature, flexibility, impact resistance, and eco-friendliness. This article delves into the application advantages of PE foam sheets across industries such as packaging, electronics, healthcare, and logistics, exploring their physical properties, design adaptability, and sustainability. Additionally, it addresses frequently asked questions to guide businesses in selecting the optimal solution to enhance the safety of product transportation.

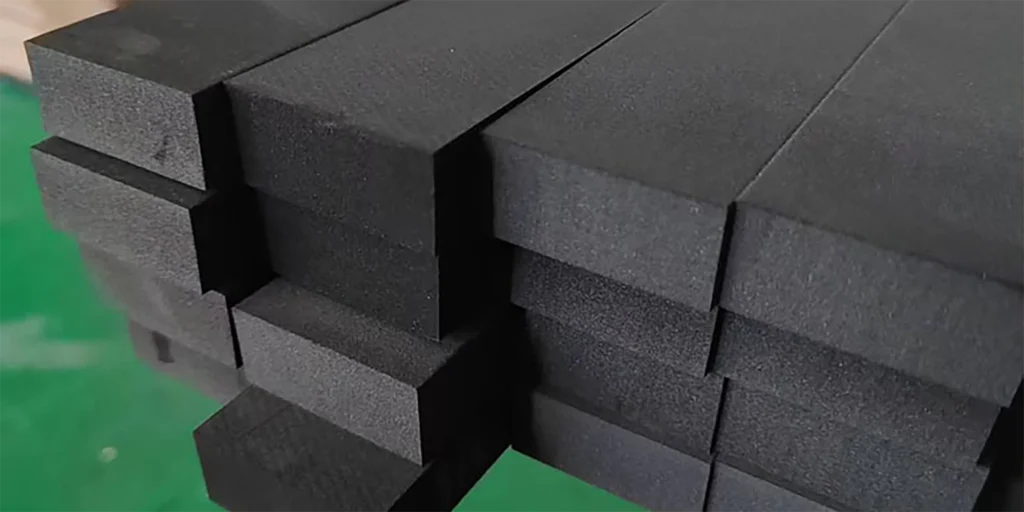

Characteristics and Industrial Applications of PE Foam Sheets

- Why Choose PE Foam Sheets?

- Exceptional Cushioning Performance: The closed-cell structure effectively absorbs impact energy, mitigating vibrations and safeguarding delicate items such as precision instruments and electronic devices.

- Lightweight Design: With a low density (30-200 kg/m³), it reduces packaging weight and lowers transportation costs.

- Chemical Resistance: Resistant to water, oils, and most chemical solvents, making it ideal for damp or corrosive environments, including cold-chain logistics.

- Eco-Friendly and Recyclable: Fully recyclable and compliant with RoHS and REACH regulations, aligning with the growing demand for sustainable packaging.

- Application Scenarios

- Electronics Packaging: Protective cushioning for fragile devices such as smartphones, tablets, and cameras.

- Medical Device Protection: Sterile shock-absorbing layers for the transportation of medical equipment.

- Furniture and Construction Material Safeguarding: Shock isolation for fragile items like glass and ceramics during long-distance transit.

- Automotive Industry: Scratch-resistant protective films for components such as doors and dashboards.

Design and Processing of PE Foam Sheets

- Customization Services: Supports precision cutting, laminating, and die-cutting to accommodate diverse shapes and dimensions.

- Multi-Layer Composite Structures: Enhanced flame-retardant or thermal insulation properties when combined with materials like aluminum foil or PET film.

- Cost-Effective Production: Low mold costs, making it suitable for small-batch customized manufacturing.

Comparison: PE Foam vs. Other Cushioning Materials

| Material | Advantages | Disadvantages |

|---|---|---|

| PE Foam Sheets | Lightweight, flexible, eco-friendly | Limited high-temperature resistance (<80°C) |

| EPS Foam | Low cost, high rigidity | Brittle, non-recyclable |

| PU Foam | High elasticity, superior sound absorption | Higher cost, slow degradation |

Frequently Asked Questions

Q1: What is the maximum temperature tolerance of PE foam sheets?

A: Standard PE foam sheets operate within a temperature range of -60°C to 80°C. For high-temperature environments, modified materials such as cross-linked polyethylene (IXPE) are recommended.

Q2: How can I determine if the cushioning performance of PE foam meets standards?

A: Testing parameters such as density, compression strength, and rebound rate, along with simulated transport conditions (e.g., ISTA drop tests), are essential for evaluation.

Q3: Are PE foam sheets suitable for food-grade packaging?

A: Yes, FDA-certified PE materials are safe for food-contact packaging, provided they are free from additive contamination.

Q4: What environmental benefits does PE foam offer over EPS?

A: PE foam is recyclable and does not release toxic substances during degradation, whereas EPS is non-biodegradable and emits harmful gases when incinerated.

Q5: Can brand logos be printed onto PE foam surfaces?

A: UV printing, screen printing, or labeling is possible, but solvent-free inks should be selected to prevent material degradation.

As an innovative choice for shock absorption and cushioning solutions, PE foam sheets are driving the packaging industry toward greater efficiency and environmental sustainability, thanks to their cost-effectiveness and versatility. Businesses should evaluate product-specific requirements and transportation conditions to tailor the ideal cushioning solution.

WELLE Trade has over 20 years of experience in the production and processing of PE/EVA/TPE foams, so you may want to consult with them if you have any sourcing needs.