Abstract:

The fabrication of PE (Polyethylene) Foam custom-shaped products represents a high-precision molding process tailored to specialized requirements, widely employed in sectors such as electronic packaging, medical devices, and automotive manufacturing. Utilizing techniques like thermoforming, CNC machining, and mold injection, PE Foam can be transformed into intricate structural components for cushioning, sealing, or thermal insulation. This paper examines its core value through material properties, processing methodologies, and industry trends, supplemented by an FAQ addressing common inquiries.

I. Core Technologies in PE Foam Custom Processing

1. Material Characteristics and Advantages

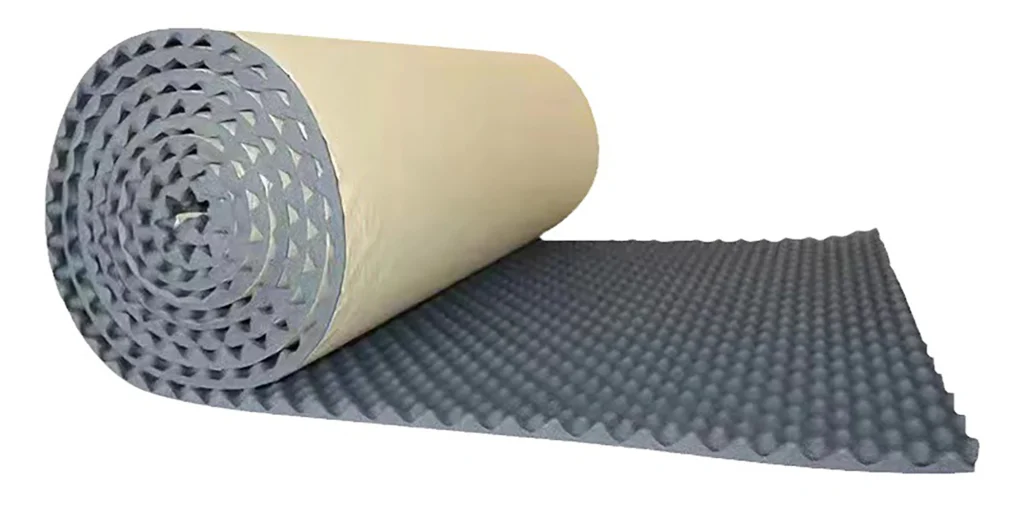

PE Foam combines lightweight properties, high elasticity, corrosion resistance, and thermal insulation, with a density range of 20–200 kg/m³. Its closed-cell structure effectively repels moisture and chemical degradation, making it an ideal substrate for custom-shaped fabrication.

2. Primary Processing Techniques

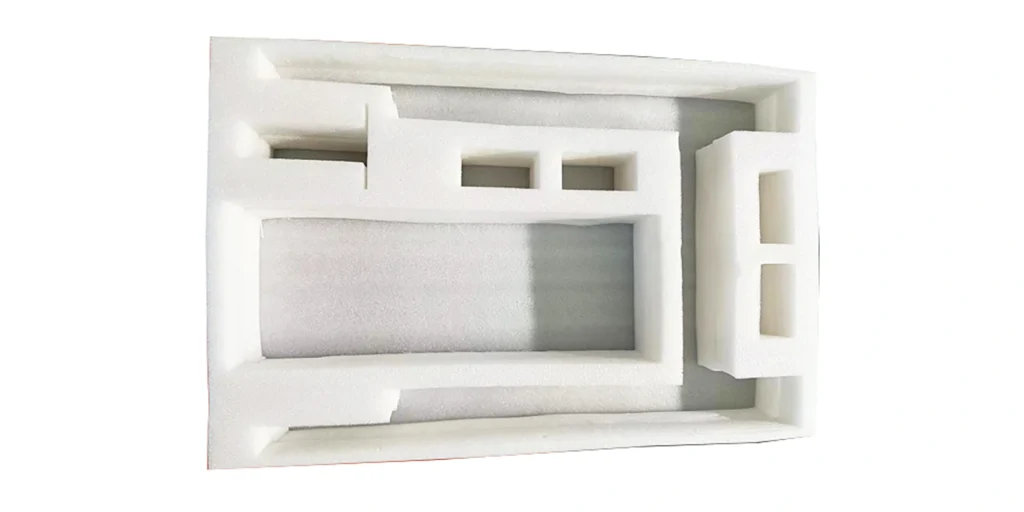

- Thermoforming: Shaping PE sheets via heated molds, ideal for mass production (e.g., protective inserts for express packaging).

- CNC Machining: Precision cutting of complex geometries for small-batch components (e.g., thermal insulation brackets for medical equipment).

- Foam Injection Molding: Direct injection with foaming agents for ultra-lightweight shapes (e.g., shock-absorbing mounts for drones).

3. Industry Applications

- Electronics: Vibration-damping liners for camera lenses, sealing gaskets for server racks.

- Automotive: Thermal barriers for EV battery modules, waterproof door seals.

- Construction: Pipe insulation sleeves, rooftop moisture barriers.

II. Technical Challenges and Emerging Trends

1. Key Challenges

- Dimensional precision (±0.1mm tolerance control)

- Surface finish (minimizing bubbles or burrs)

- Cost efficiency (custom small-batch costs exceeding 60% of total expenses)

2. Innovations Shaping the Industry

- Smart Mold Design: 3D-printed molds reduce development cycles to 3–7 days.

- Biodegradable PE Foam: Bio-based alternatives growing at 25% annually to meet eco-regulations.

- Full Automation: AI-integrated QC systems reduce defect rates below 0.3%.

FAQ: Addressing Key Queries

Q1: How does PE Foam processing differ from EVA?

A: While both support thermoforming, PE Foam excels in chemical resistance, whereas EVA offers superior elasticity. For oil-exposed applications (e.g., automotive parts), PE Foam is preferred.

Q2: What is the MOQ for custom small batches?

A: CNC machining permits single-unit orders, though costs are ~40% higher than bulk. Orders of 10+ units optimize pricing.

Q3: How to ensure long-term product stability?

A: UV stabilization (anti-yellowing) and cross-linking (enhanced durability) extend lifespan to 8–10 years.

Q4: What thickness ranges are feasible?

A: Standard PE sheets span 1–50mm; ultra-thick profiles (e.g., 100mm) require multi-layer thermal fusion.

PE Foam custom processing is evolving from basic packaging to functional, precision-driven solutions. With booming demand in EVs and 5G infrastructure, the global market is projected to exceed $3.8 billion by 2025. Enterprises must prioritize adaptive manufacturing and sustainable materials to thrive in this competitive landscape.

WELLE Trade has over 20 years of experience in the production and processing of PE/EVA/TPE foams, so you may want to consult with them if you have any sourcing needs.