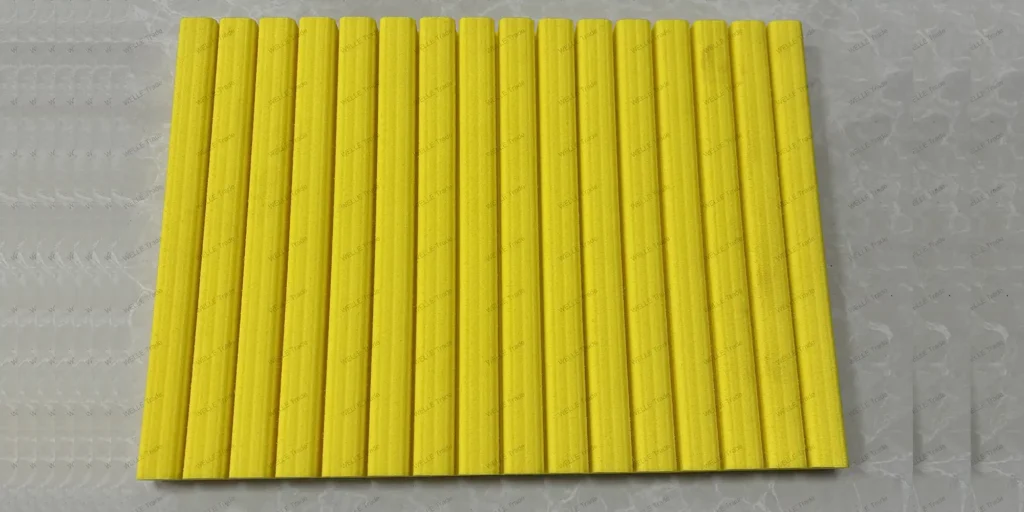

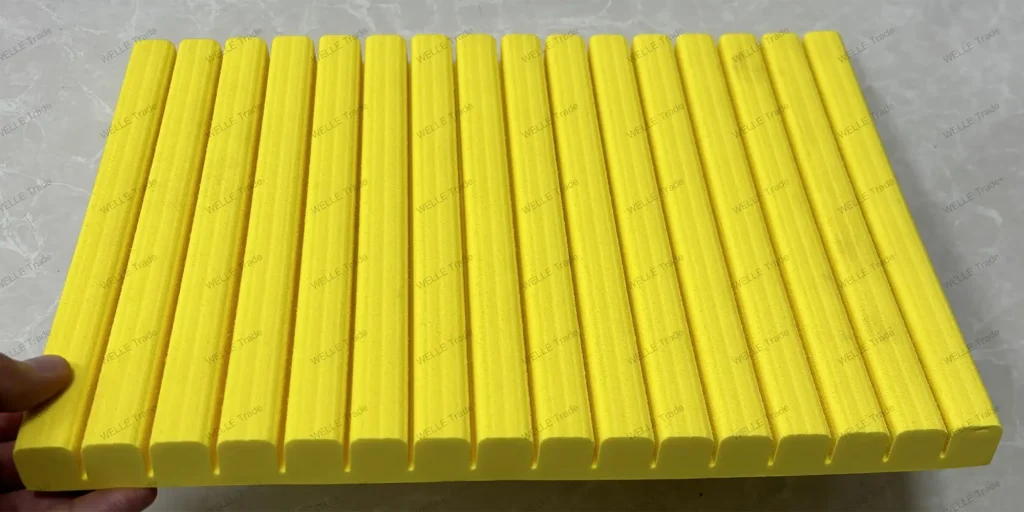

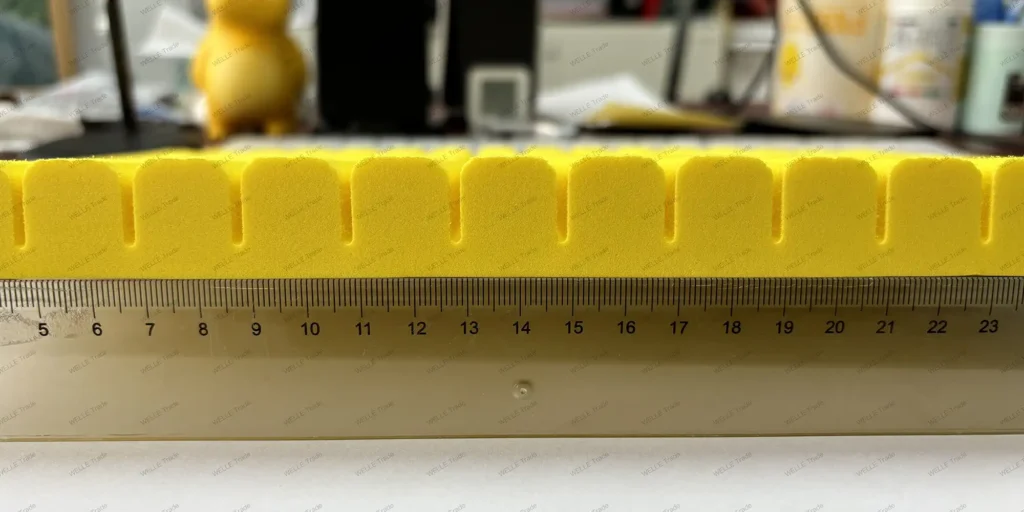

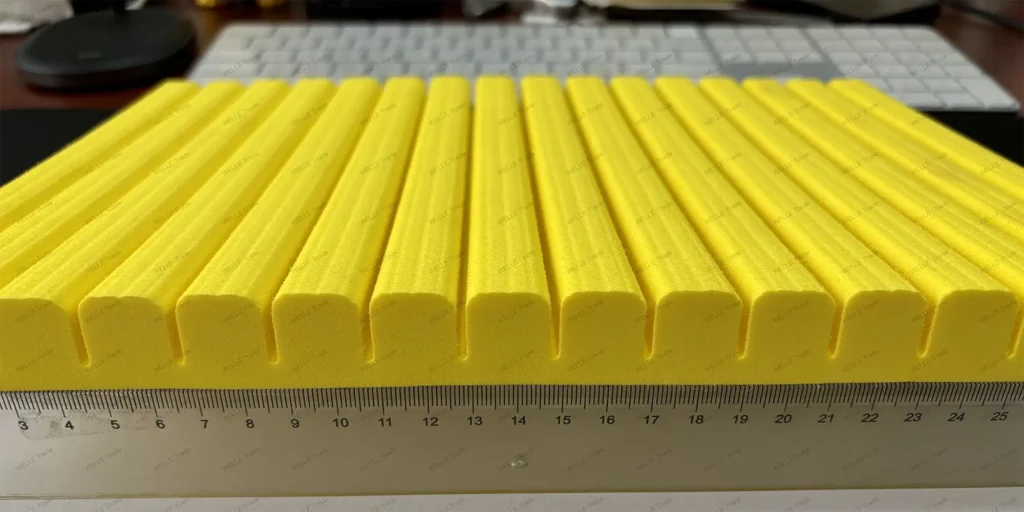

EVA foam padding is a versatile material widely used across various industries, from sports and fitness to construction and packaging. With its flexibility, durability, and ease of customization, EVA foam has become a sought-after product for businesses looking to expand their product offerings and enter new markets. However, navigating the international market for EVA foam padding involves several key considerations, particularly when it comes to importing products and meeting safety standards in different countries. This article will explore these factors and share success stories of businesses that have successfully imported EVA foam padding for large-scale projects.

Key Considerations for Importing EVA Foam Products

When importing EVA foam padding, businesses need to consider several factors to ensure a smooth and successful transaction. Here are some of the key considerations:

1. Understanding Market Demand

Before diving into the import business, it’s crucial to understand the demand for EVA foam products in your target market. Conducting thorough market research can help identify the types of EVA foam products that are in high demand, as well as potential competitors and pricing strategies. This knowledge can help businesses tailor their product offerings to meet the needs of their target customers.

2. Choosing Reliable Suppliers

Finding reliable suppliers is a cornerstone of a successful import business. When choosing a supplier for EVA foam padding, it’s important to consider factors such as the quality of the products, the supplier’s reputation, their production capacity, and their ability to meet delivery deadlines. Businesses should also ensure that the supplier adheres to international standards and regulations for EVA foam products.

3. Navigating Import Regulations

Importing EVA foam products involves adhering to various regulations and standards set by the importing country. These regulations may include product safety standards, environmental regulations, and import tariffs. Businesses should familiarize themselves with the specific requirements of the countries they are importing to and work with experienced customs brokers or legal advisors to ensure compliance.

4. Cost Management

Cost management is another critical factor in the import business. Businesses should consider all costs associated with importing EVA foam products, including shipping fees, customs duties, and taxes. By carefully managing these costs, businesses can maintain competitive pricing while ensuring a healthy profit margin.

How to Meet the Safety Standards of Different Countries with EVA Foam Padding

Meeting the safety standards of different countries is essential for businesses importing EVA foam padding. Here are some strategies to ensure compliance:

1. Understanding International Safety Standards

Different countries have varying safety standards for EVA foam products. For example, the European Union has stringent regulations under the REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) framework, while the United States follows standards set by agencies such as the Consumer Product Safety Commission (CPSC) and the Environmental Protection Agency (EPA). Businesses should familiarize themselves with these standards to ensure their products meet all necessary requirements.

2. Testing and Certification

To ensure compliance with safety standards, businesses should have their EVA foam products tested by accredited laboratories. Obtaining certifications from recognized bodies can also provide assurance to customers and regulatory authorities that the products meet the required safety standards. Certifications such as ISO (International Organization for Standardization) can enhance the credibility of the products and facilitate smoother import processes.

3. Collaborating with Experts

Partnering with experts in regulatory compliance can help businesses navigate the complexities of international safety standards. Legal advisors, regulatory consultants, and certification bodies can provide valuable insights and guidance, ensuring that all necessary steps are taken to comply with the regulations of the target market.

Success Stories: Importing EVA Foam Padding for Large-Scale Projects

Several businesses have successfully imported EVA foam padding for large-scale projects, demonstrating the potential of this versatile material in the global market. Here are a few success stories:

1. Sports Equipment Manufacturer Expands Product Line

A leading sports equipment manufacturer in the United States sought to expand its product line to include high-quality EVA foam padding for use in protective gear. By partnering with a reliable supplier in Asia and adhering to the CPSC standards, the company was able to successfully import EVA foam products that met the safety requirements. This allowed them to offer a new range of products, resulting in a significant increase in sales and market share.

2. Construction Firm Sources Eco-Friendly EVA Foam

A construction firm in Europe needed eco-friendly EVA foam padding for a large-scale infrastructure project. By sourcing products from a supplier that adhered to the EU’s REACH regulations, the firm was able to ensure that the EVA foam used in their project was safe for the environment and met all regulatory standards. This move not only helped the firm secure the project but also positioned them as a leader in sustainable construction practices.

3. Packaging Company Introduces Custom EVA Foam Solutions

A packaging company in Canada wanted to offer custom EVA foam padding solutions to its clients in the electronics industry. By importing EVA foam products that were compliant with North American safety standards, the company was able to provide tailored solutions that met the specific needs of their clients. This customization capability set them apart from competitors and helped them secure long-term contracts with major electronics manufacturers.

Importing EVA foam padding can be a lucrative venture for businesses looking to diversify their product offerings and enter new markets. However, it requires careful planning, a thorough understanding of market demands, and strict adherence to international safety standards. By choosing reliable suppliers, managing costs effectively, and ensuring compliance with regulations, businesses can successfully navigate the international market for EVA foam padding and achieve long-term success.

FAQ

1. What is EVA foam padding, and why is it popular?

EVA foam padding is a versatile material made from ethylene-vinyl acetate, known for its flexibility, durability, and shock absorption properties. It is popular in various industries, including sports, construction, and packaging, due to its ability to provide cushioning and protection.

2. What should I consider when importing EVA foam products?

Key considerations for importing EVA foam products include understanding market demand, choosing reliable suppliers, navigating import regulations, and managing costs effectively to maintain competitive pricing.

3. How can I ensure my EVA foam products meet international safety standards?

To ensure compliance with international safety standards, businesses should familiarize themselves with the specific regulations of the target market, conduct testing and certification through accredited laboratories, and collaborate with regulatory experts.

4. What are some success stories of importing EVA foam padding?

Several businesses have successfully imported EVA foam padding for large-scale projects, including sports equipment manufacturers expanding their product lines, construction firms sourcing eco-friendly materials, and packaging companies offering custom solutions.

5. How do I choose a reliable supplier for EVA foam padding?

Choosing a reliable supplier involves assessing the quality of the products, the supplier’s reputation, production capacity, adherence to international standards, and ability to meet delivery deadlines.

#EVAfoam #ImportBusiness #GlobalTrade #SafetyStandards #ProductSourcing #MarketExpansion #EcoFriendlyMaterials #BusinessSuccess #SupplyChain #CustomSolutions

WELLE Trade has over 20 years of experience in the production and processing of PE/EVA/TPE foams, so you may want to consult with them if you have any sourcing needs.