Thermoplastic Elastomer (TPE) foam is a versatile and innovative material that has gained significant popularity in various industries due to its unique properties and broad range of applications. This comprehensive guide will delve into the composition, characteristics, and uses of TPE foam, making it a valuable resource for newcomers looking to understand how this material works and why it is widely used across different sectors.

What Is TPE Foam?

TPE foam, short for Thermoplastic Elastomer foam, is a type of foam made from a combination of thermoplastic and elastomer materials. Unlike traditional rubber, TPE foam has the unique ability to combine the elasticity and flexibility of rubber with the processability of thermoplastics. This makes it an attractive choice for a wide range of applications, from automotive components to medical devices.

TPE foam is created through a molding process where a mixture of polymer compounds is heated and expanded into a foam-like structure. The result is a material that offers both the softness and flexibility of rubber and the durability and recyclability of thermoplastics.

Key Characteristics of TPE Foam

1. Elasticity and Flexibility

TPE foam exhibits remarkable elasticity, meaning it can return to its original shape after being compressed or deformed. This makes it ideal for applications that require cushioning, shock absorption, or sealing properties. The flexibility of TPE foam allows it to be molded into complex shapes without losing its structural integrity.

2. Durability

TPE foam is highly durable, resistant to wear, and maintains its performance over time. It can withstand harsh environmental conditions, including temperature fluctuations, moisture, and UV exposure, making it suitable for outdoor and heavy-duty applications.

3. Lightweight

Despite its strength and durability, TPE foam is lightweight, making it an ideal material for industries that require materials with a low weight-to-strength ratio. This characteristic is especially useful in automotive and aerospace industries where weight reduction is a priority.

4. Recyclability

One of the most attractive aspects of TPE foam is its recyclability. Unlike many other foamed materials, TPE foam can be easily reprocessed and reused without significantly losing its performance. This makes it a more eco-friendly option, especially as companies increasingly look for sustainable materials.

5. Non-Toxic and Safe

TPE foam is generally considered non-toxic, making it a safe option for various applications, particularly in consumer products and medical devices. It does not contain harmful chemicals like PVC, phthalates, or latex, which are often found in other foam materials.

How Does TPE Foam Work?

The working principle of TPE foam lies in the combination of thermoplastic and elastomer materials. The thermoplastic component gives the foam its moldability and recyclability, while the elastomer component provides the flexibility and resilience needed for cushioning and impact resistance.

When heated, TPE foam becomes soft and pliable, allowing it to be molded into various shapes. Upon cooling, it solidifies and retains its new form. This reversible process makes TPE foam highly versatile for different manufacturing methods, including injection molding, compression molding, and extrusion.

Common Applications of TPE Foam

1. Automotive Industry

TPE foam is widely used in the automotive industry for applications such as sealing strips, gaskets, and insulation. Its excellent shock-absorbing properties and ability to resist wear and environmental degradation make it an ideal choice for parts exposed to heavy use and extreme weather conditions.

2. Medical Devices

The medical industry also makes extensive use of TPE foam due to its non-toxic nature and biocompatibility. It is often used in the manufacture of medical gloves, wound care products, and cushioning for medical devices. Its soft, flexible texture provides comfort and protection for patients while also being durable and easy to sterilize.

3. Sports Equipment

TPE foam is commonly found in sports equipment, particularly in items that require cushioning or shock absorption. For example, it is used in padding for helmets, knee pads, and other protective gear. Its ability to absorb impact makes it an essential material for enhancing safety in sports.

4. Packaging

TPE foam is used in packaging to provide cushioning and protect fragile items during shipping. Its lightweight, flexible nature ensures that products are securely protected from damage, while its durability ensures that the packaging holds up during transit.

5. Consumer Goods

In addition to the above industries, TPE foam is also used in a variety of consumer goods, including footwear, furniture cushions, and household items. Its softness, comfort, and ability to conform to different shapes make it a popular material in the production of everyday items.

Advantages of TPE Foam Over Other Materials

- Superior Flexibility: TPE foam offers greater flexibility compared to traditional foams like EVA (Ethylene-Vinyl Acetate) or polyurethane foam, making it a better choice for applications requiring a high degree of movement.

- Environmental Benefits: TPE foam is a more sustainable choice compared to PVC or other non-recyclable foam materials. Its recyclability ensures that it has a lower environmental impact, making it a preferred option for eco-conscious industries.

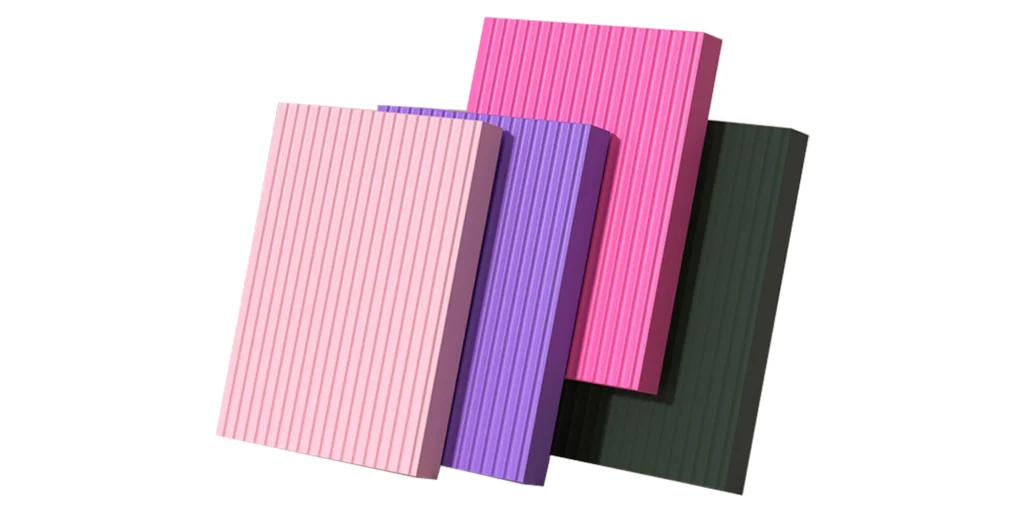

- Customization: TPE foam can be easily modified to meet specific requirements. It can be produced in a range of densities, colors, and forms, allowing manufacturers to tailor it to their unique needs.

- Cost-Effectiveness: While TPE foam can be more expensive than some alternatives, its durability, recyclability, and performance often provide a better long-term investment, especially in high-demand applications.

TPE foam is an incredibly versatile material that provides a unique combination of flexibility, durability, and sustainability. From automotive components to medical devices, TPE foam’s diverse applications and advantages make it an essential material in numerous industries. Its ability to offer high performance while being environmentally friendly makes it a great choice for businesses looking to innovate and meet the demands of modern markets.

Whether you are involved in manufacturing, product development, or just looking to learn more about materials, understanding the composition and characteristics of TPE foam can provide valuable insights into its potential uses and benefits.

am eco-friendly?

Yes, TPE foam is considered eco-friendly because it is recyclable and does not contain harmful chemicals such as PVC or phthalates. This makes it a safer and more sustainable choice compared to other foam materials.

3. What are the main benefits of TPE foam?

TPE foam offers several benefits including superior elasticity, flexibility, durability, lightweight properties, and recyclability. It is also non-toxic, making it safe for use in medical devices and consumer products.

4. Where is TPE foam commonly used?

TPE foam is widely used in industries such as automotive (seals and gaskets), medical devices (cushioning and gloves), sports equipment (impact protection), packaging (cushioning fragile goods), and consumer products (footwear and furniture).

5. How is TPE foam produced?

TPE foam is produced by heating a mixture of thermoplastic and elastomer materials, which expands into a foam-like structure. This process can be done using molding techniques such as injection molding, extrusion, and compression molding.

FAQ: TPE Foam

1. What is TPE foam made of?

TPE foam is a combination of thermoplastic materials and elastomers. The thermoplastic component allows it to be molded and recycled, while the elastomer provides the flexibility and cushioning properties of the foam.

2. Is TPE foam eco-friendly?

Yes, TPE foam is considered eco-friendly because it is recyclable and does not contain harmful chemicals such as PVC or phthalates. This makes it a safer and more sustainable choice compared to other foam materials.

3. What are the main benefits of TPE foam?

TPE foam offers several benefits including superior elasticity, flexibility, durability, lightweight properties, and recyclability. It is also non-toxic, making it safe for use in medical devices and consumer products.

4. Where is TPE foam commonly used?

TPE foam is widely used in industries such as automotive (seals and gaskets), medical devices (cushioning and gloves), sports equipment (impact protection), packaging (cushioning fragile goods), and consumer products (footwear and furniture).

5. How is TPE foam produced?

TPE foam is produced by heating a mixture of thermoplastic and elastomer materials, which expands into a foam-like structure. This process can be done using molding techniques such as injection molding, extrusion, and compression molding.

#TPEFoam #ThermoplasticElastomer #EcoFriendlyMaterials #SustainableManufacturing #MedicalDevices #AutomotiveParts #SportsEquipment #PackagingSolutions #FoamTechnology #RecyclableMaterials #InnovationInMaterials #ConsumerGoods #FoamApplications

WELLE Trade has over 20 years of experience in the production and processing of PE/EVA/TPE foams, so you may want to consult with them if you have any sourcing needs.