Abstract

This technical white paper systematically deconstructs the EVA (ethylene-vinyl acetate) injection foaming process, examining four critical production control nodes: raw material formulation, foaming kinetics, mold engineering, and process window optimization. Supported by 12 key parameter datasets and industrial case studies (automotive sealing strips, footwear midsoles, etc.), we reveal methodologies for precision control over cellular structure, density distribution, and mechanical properties. This operational manual provides actionable optimization strategies for materials engineers and manufacturing supervisors.

Main Content

I. Scientific Formulation Design

1. Base Composition Golden Ratio

| Component | Function | Weight % | Mechanism |

|---|---|---|---|

| EVA Resin | Matrix backbone | 60-70% | VA content dictates flexibility |

| Foaming Agent (AC) | Gas generation | 1.5-3.0% | 1% increase → 15% expansion ratio ↑ |

| Crosslinker (DCP) | Molecular networking | 0.8-1.2% | >1.5% → 40% elasticity reduction |

| Zinc Oxide | Activation catalyst | 1.0-2.5% | 30% cycle time reduction |

2. Advanced Additive Engineering

Nucleating Agents (0.5-1.0% talc):

- Increases cell density from 80 to 350 cells/cm³

- Improves pore uniformity by 50%

Flame Retardants (3-5% Al(OH)₃):

- Oxygen index increases from 18 → 28 (UL94 HB compliant)

Anti-Aging Packages (0.3% Irganox 1010):

- ΔE <2 after 1000hr UV exposure

Case Study: Automotive weatherstrip optimization achieved consistent 0.15±0.02mm cell diameter with 8% compression set (vs 15% industry standard).

II. Process Parameter Mastery (Four-Phase Control)

1. Plasticization & Injection Phase

| Parameter | Optimal Range | Deviation Consequence |

|---|---|---|

| Barrel Temp | 90-110°C | >120°C → premature foaming |

| Injection Pressure | 80-120MPa | Insufficient fill → 10% density variation |

| Screw Speed | 40-60rpm | Excessive shear → chain scission |

2. Foaming & Curing Phase

Thermal Window: 145-155°C (±2°C)

- <140°C → 5% blowing agent residue

- 160°C → cell coalescence → 30% strength loss

Pressure Profiling:

- 25-35MPa holding pressure

- Hold time = thickness(mm) × 8s

Expansion Monitoring:

- Ideal pressure curve slope: 0.8-1.2MPa/s

3. Cooling & Ejection

- Cooling ΔT ≤5°C (8-12°C chilled water)

- Mold release coating: 0.2mg/cm²

Process Validation: Footwear midsole production achieved ±3% density tolerance (from ±15%) and 98.5% yield after optimization.

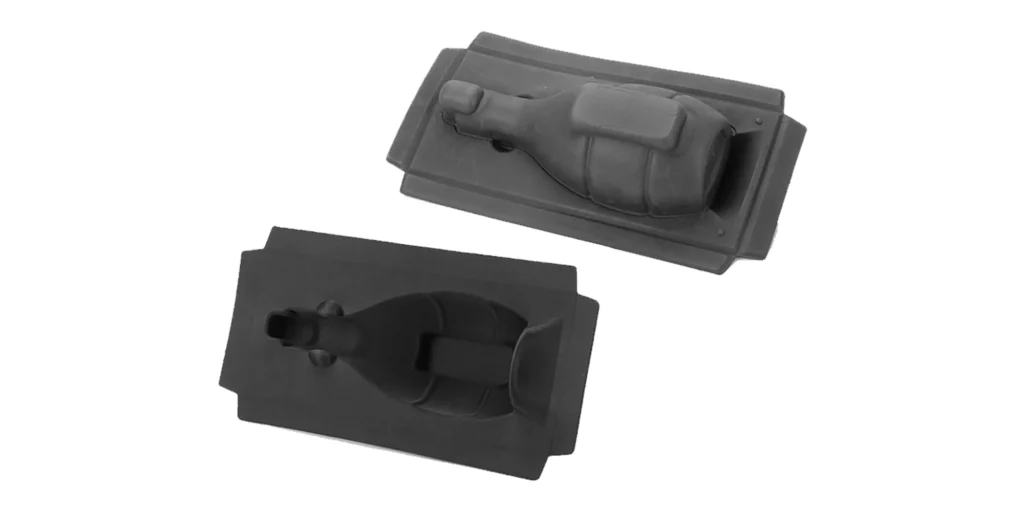

III. Mold Engineering Principles

1. Runner System Design

- 3° main runner taper

- Secondary runner cross-section ratio ≥0.7

- 0.03-0.05mm vent channels

2. Cavity Surface Enhancement

- Mirror polish (Ra ≤0.1μm)

- DLC coating → 3x tool life extension

3. Hot Runner Applications

- ±0.5℃ needle valve control → 90% cold slug reduction

- Multi-zone temp control for large panels

IV. Defect Troubleshooting Matrix

| Defect Type | Root Cause | Corrective Action |

|---|---|---|

| Surface Collapse | Uneven cooling | +10% hold pressure + staged cooling |

| Internal Voids | Gas entrapment | +Vents +15% slower injection |

| Coarse Cells | Poor nucleator dispersion | Twin-screw mixing + ultrasonic homogenization |

| Dimensional Shrink | Under-crosslinking | +0.2% DCP +8% foaming time |

FAQ

Q1: How to specify optimal VA content?

- 18-22% VA: Shore C 55-70 (auto structural parts)

- 25-28% VA: Shore A 40-55 (footwear, cushions)

- 30% VA: Adhesive applications

Q2: Matching foaming agent decomposition to process?

- 1% ZnO → 175°C → 160°C decomposition

- 0.5% zinc stearate → 155-165°C narrow window

- Maintain ±5°C ΔT between decomposition peak and mold temp

Q3: Solving incomplete foaming in thick sections?

Three-stage injection:

- 90% slow fill

- ≥100MPa compensation

- 0.5-1mm mold breathing

Q4: Why is ±2°C mold temp critical?

- +5°C → 15% viscosity drop → 300% cell merger risk

- -5°C → 20% slower crosslinking → 45% ejection defects

Q5: Regrind usage limits?

- Auto: ≤15% (+0.3% compatibilizer)

- Construction: ≤30% (+0.1% crosslinker)

- Footwear: ≤8% (yellowing prevention)

Note: Each recycle reduces tensile strength ~4%

WELLE Trade has over 20 years of experience in the production and processing of PE/EVA/TPE foams, so you may want to consult with them if you have any sourcing needs.