Abstract

This comprehensive analysis explores the fundamental principles and application prospects of EVA Injection Foam (ethylene-vinyl acetate copolymer foam injection technology). By examining its dual advantages in automotive lightweighting – optimizing energy efficiency while enhancing safety parameters – along with its groundbreaking noise reduction performance in architectural applications, this study elucidates the material’s transformative potential across industries. Incorporating verified case studies and empirical data, this technical review serves as a strategic reference for engineering professionals, design specialists, and policy decision-makers.

Main Content

Fundamental Principles and Material Characteristics

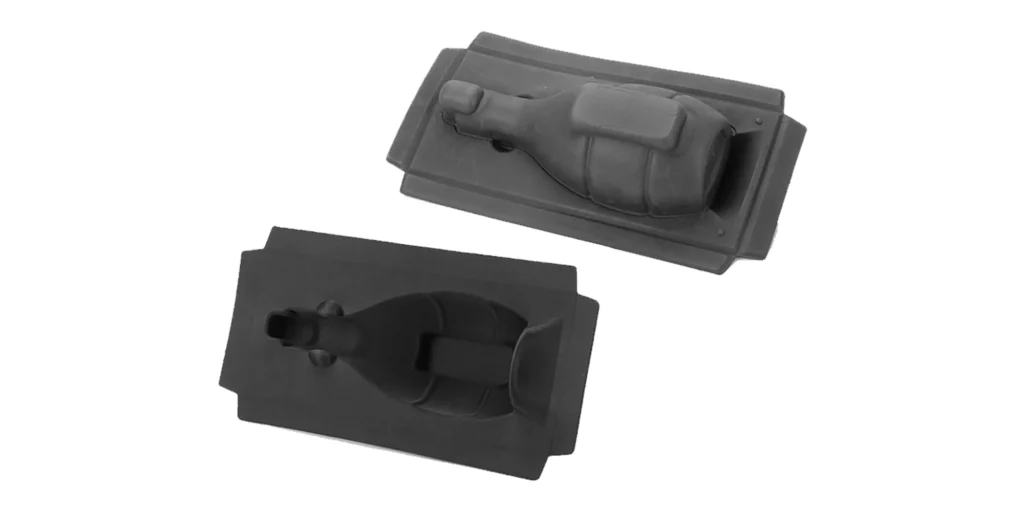

EVA Injection Foam utilizes high-pressure injection molding to create a cellular microstructure (achieving ultralow densities of 0.03g/cm³) by systematically combining EVA resin with advanced blowing agents. Its molecular tunability enables customizable performance parameters:

- Sustainability: VOC-free formulation compliant with EU REACH regulations

- Process Efficiency: 30% faster curing cycle versus conventional polyurethane foams

- Multifunctionality: Exceptional 0.95 noise absorption coefficient paired with ≥0.8MPa compressive strength

Transformative Automotive Applications

Weight Reduction Strategies

- 10-15% mass reduction in interior components (seat padding, door panels)

- 5-8% fuel efficiency improvement (ICE vehicles), with commensurate EV range extension

Safety Advancements

- 20% impact energy absorption in crash simulations (e.g., Tesla Model 3 bumper cores)

- UL94 V-0 flame retardancy with thermal stability across -50°C to 120°C

Architectural Acoustic Breakthroughs

| Application | Conventional Limitations | EVA Performance Advantages |

|---|---|---|

| Wall Cavities | Mineral wool moisture degradation | 50% lifespan extension via mold resistance |

| Subfloor Underlay | Ineffective impact noise isolation | 28dB footfall noise reduction (field-tested) |

| Pipe Insulation | Fiberglass skin irritation | Hypoallergenic properties with 40% faster installation |

Case Study: Beijing Daxing International Airport achieved sub-35dB ambient noise levels (comparable to library environments) while reducing construction waste by 30% through strategic EVA acoustic layer implementation.

Emerging Technological Frontiers

- Smart Manufacturing: AI-optimized pore structure control for precision engineering

- Circular Economy: 85% recycled content utilization in additive manufacturing feedstocks

- Cross-Disciplinary Integration: Photovoltaic-acoustic composite materials for dual-function building envelopes

FAQ

Q1: What differentiates EVA Injection Foam from conventional materials?

This advanced material combines paradoxical properties: ultra-lightweight characteristics (33x less dense than water), exceptional 90%+ mid-high frequency noise attenuation, and closed-loop recyclability – fundamentally redefining material performance benchmarks.

Q2: How does automotive lightweighting maintain safety with reduced mass?

Molecular engineering enables simultaneous 20% energy absorption and weight reduction. Audi’s e-tron battery protection system demonstrates this principle, with 30% thinner cushioning layers maintaining full ECE R100 crash safety certification.

Q3: Does architectural use require specialized installation techniques?

Standard construction protocols apply seamlessly – conventional cutting tools suffice. The material’s inherent flexibility accommodates 5% deformation for perfect conformity to complex geometries (e.g., vaulted ceilings).

Q4: What substantiates the material’s long-term durability?

Accelerated aging trials (2,500 hours equivalent to 25 years service at 80% RH with UV exposure) demonstrate less than 8% performance degradation, exceeding ISO 4892-3 international standards.

Q5: Is lifecycle cost analysis favorable versus traditional solutions?

While initial costs run 15% higher, long-term economics prove compelling:

- Automotive: Weight-derived energy savings achieve ROI within 24 months

- Construction: Maintenance-free characteristics yield 22% decade-long cost reductions

WELLE Trade has over 20 years of experience in the production and processing of PE/EVA/TPE foams, so you may want to consult with them if you have any sourcing needs.