Introduction

The construction and architectural industries are continually seeking innovative solutions to enhance energy efficiency and provide optimal thermal comfort. One such solution that has gained significant traction in recent years is the use of EVA foam in thermal breaks. This article delves deep into the world of EVA foam and its transformative role in thermal break products.

Understanding EVA Foam

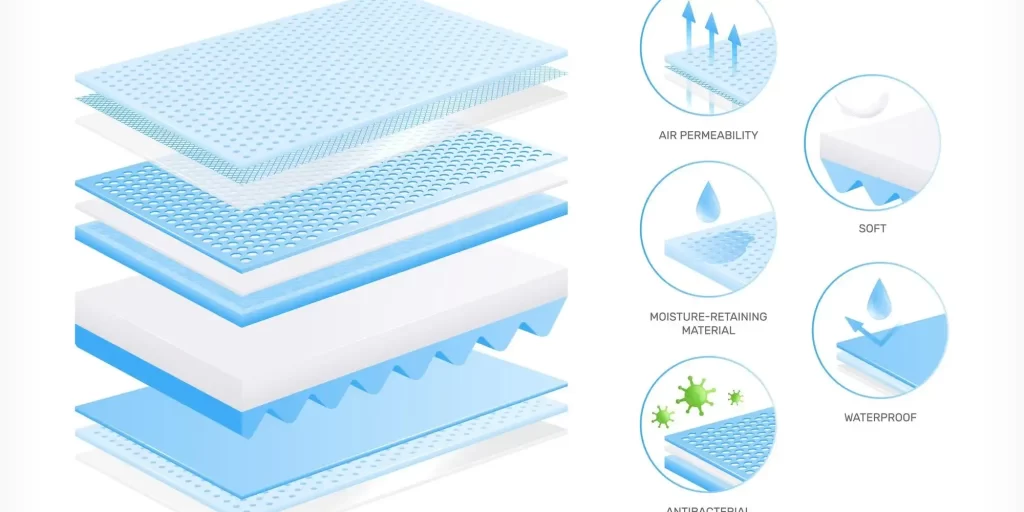

EVA, or Ethylene Vinyl Acetate, is a closed-cell foam known for its flexibility, resilience, and excellent insulating properties. Its unique molecular structure allows it to effectively resist the transfer of heat, making it an ideal material for thermal break applications.

The Role of EVA Foam in Thermal Breaks

Thermal breaks are essential components in construction that prevent heat transfer between the interior and exterior of a structure. By integrating EVA foam into these breaks:

- Reduced Heat Transfer: EVA foam’s insulating properties significantly reduce heat transfer, helping maintain a consistent indoor temperature.

- Energy Efficiency: With minimized heat loss or gain, HVAC systems work more efficiently, leading to reduced energy consumption and lower utility bills.

- Condensation Control: EVA foam prevents the formation of condensation on surfaces, protecting structures from potential moisture damage.

- Enhanced Comfort: EVA foam thermal breaks ensure a comfortable indoor environment, regardless of external weather conditions.

Applications of EVA Foam in Thermal Breaks

- Window and Door Frames: EVA foam is commonly used in the frames of windows and doors to prevent heat transfer and eliminate cold bridges.

- Building Facades: EVA foam thermal breaks are integrated into building facades to enhance energy efficiency.

- Roofing Systems: EVA foam can be used in roofing systems to provide an insulating barrier against heat.

- Flooring Systems: EVA foam thermal breaks can be incorporated into flooring systems, especially in multi-story buildings, to prevent heat transfer between floors.

Advantages of Using EVA Foam in Thermal Breaks

- Durability: EVA foam is resistant to wear and tear, ensuring longevity in thermal break applications.

- Lightweight: EVA foam’s lightweight nature makes it easy to handle and install.

- Cost-Effective: EVA foam offers a cost-effective solution for thermal insulation compared to other materials.

- Eco-Friendly: EVA foam is recyclable, aligning with sustainable building practices.

FAQ

Q: How does EVA foam compare to other materials used in thermal breaks?

A: EVA foam offers superior thermal insulation, durability, and cost-effectiveness compared to many traditional materials.

Q: Can EVA foam thermal breaks be used in extreme weather conditions?

A: Yes, EVA foam is resilient and can withstand a range of temperatures, making it suitable for various climatic conditions.

Q: How do EVA foam thermal breaks contribute to green building certifications?

A: EVA foam’s energy efficiency and recyclability can contribute to points in green building certification programs.

Q: Are there any limitations to using EVA foam in thermal breaks?

A: While EVA foam is versatile, it’s essential to ensure it’s appropriately installed and sealed to maximize its insulating properties.

Conclusion

EVA foam’s role in thermal breaks is a testament to its unparalleled insulating properties and versatility. As the construction industry moves towards sustainable and energy-efficient solutions, EVA foam stands out as a material that not only meets these requirements but also enhances the comfort and longevity of structures. Whether you’re an architect, builder, or homeowner, considering EVA foam for thermal breaks can lead to significant energy savings and a more comfortable living or working environment.