In the healthcare industry, the materials used in medical electronics must meet the highest standards of safety, cleanliness, and performance. Ethylene-Vinyl Acetate (EVA) foam has become an integral component in the design and manufacturing of medical electronic products. Its unique properties offer numerous benefits, from patient comfort to device durability. This article will explore the use of EVA foam in medical electronics, its advantages, and provide answers to frequently asked questions about its application.

The Importance of EVA Foam in Medical Electronics

EVA foam’s adoption in medical electronics is driven by its exceptional features:

1. Biocompatibility:

EVA foam is non-toxic and can be formulated to be biocompatible, making it safe for use in medical devices that come into contact with patients.

2. Cushioning and Comfort:

Its softness and shock-absorbing qualities provide comfort and protection for patients, particularly in devices that are worn or handled.

3. Durability:

EVA foam is resistant to cracks and stress, ensuring that medical electronics can withstand repeated use.

4. Sterilization Compatibility:

Certain grades of EVA foam can be sterilized, an essential requirement for medical applications to maintain hygiene and prevent contamination.

5. Chemical and Fluid Resistance:

EVA foam can resist various fluids and chemicals, which is crucial in environments where spills or cleaning agents are common.

Applications of EVA Foam in Medical Electronics

Wearable Devices:

EVA foam is used in wearable medical electronics, such as heart rate monitors and insulin pumps, providing a comfortable, cushioned barrier between the device and the skin.

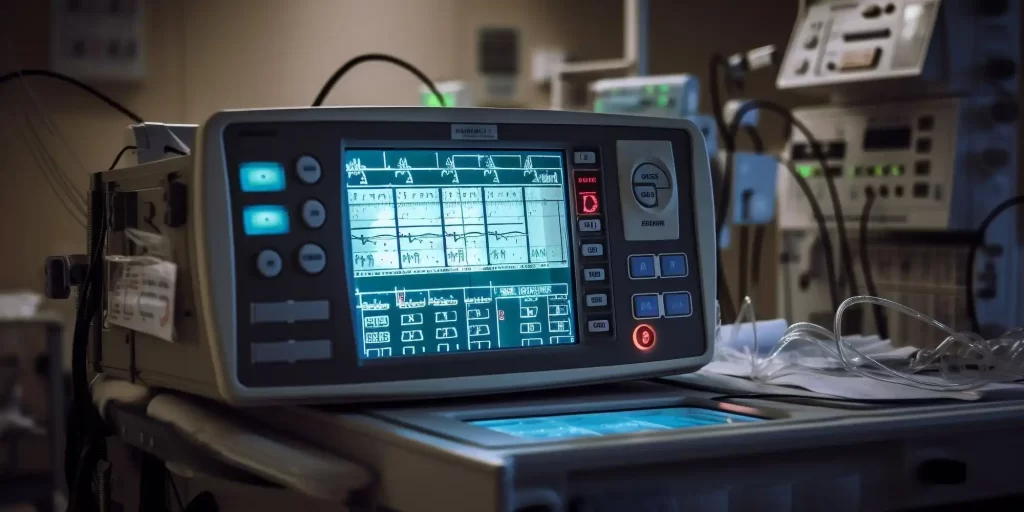

Portable Medical Equipment:

For portable medical devices like defibrillators and ultrasound machines, EVA foam offers protection and ease of handling, reducing the risk of damage during transport.

Medical Imaging Equipment:

Padding and supports made from EVA foam in MRI machines and CT scanners enhance patient comfort during long imaging sessions.

Surgical Tools and Trays:

EVA foam can be used to secure and cushion surgical instruments within trays, protecting delicate tools from damage and ensuring they remain in place.

Orthopedic and Prosthetic Devices:

Orthopedic supports and prosthetic limbs often incorporate EVA foam for its cushioning properties and comfort.

Customization and Hygiene

EVA foam can be custom-engineered to various densities, hardness levels, and shapes, making it highly adaptable to specific medical electronic needs. Additionally, its ease of cleaning and compatibility with sterilization processes align with the stringent hygiene standards of the medical industry.

FAQs About EVA Foam in Medical Electronics

Q: Is EVA foam safe for direct skin contact in medical devices?

A: Yes, when formulated for biocompatibility, EVA foam is safe for direct skin contact.

Q: Can EVA foam be sterilized along with medical electronics?

A: Certain grades of EVA foam are compatible with sterilization methods, but it’s important to verify with the manufacturer for specific products.

Q: How does EVA foam contribute to the durability of medical electronics?

A: EVA foam’s resistance to stress and impact helps protect medical electronics from damage, contributing to their durability and longevity.

Q: Are there different types of EVA foam for varying medical applications?

A: Yes, EVA foam can be produced with different properties to meet the requirements of various medical applications, from flexible and soft for patient comfort to rigid and dense for equipment protection.

Q: How does EVA foam enhance patient comfort in medical electronics?

A: Its cushioning effect reduces pressure points and provides a soft interface, enhancing comfort in devices that patients wear or come into contact with.

In conclusion, EVA foam is a vital material in the field of medical electronics, offering unmatched benefits in safety, comfort, and performance. Its versatility and adaptability make it ideal for a wide range of medical applications, from handheld devices to large diagnostic equipment. As medical technology continues to advance, the role of EVA foam is set to expand, ensuring that medical devices remain safe, effective, and comfortable for all users. With its contribution to the healthcare industry, EVA foam is truly a material that stands at the intersection of innovation and care.