Abstract

Amidst the exponential growth of e-commerce logistics, achieving equilibrium between lightweight packaging and environmental sustainability has become a pivotal challenge for the industry. This paper provides an in-depth analysis of how technological innovations in lightweight polyethylene (PE) foam simultaneously meet rigorous protective requirements while addressing circular design principles, plastic reduction targets, and decarbonization goals – offering sustainable packaging solutions.

The Rise of Lightweight PE Foam

The surge in global parcel volume has exacerbated environmental burdens from conventional packaging. According to the 2023 Global Express Packaging Whitepaper, annual waste growth reaches 15%. Lightweight PE foam (low-density polyethylene foam), featuring 30% weight reduction and superior malleability compared to traditional materials, emerges as the sustainable alternative to corrugated fiberboard and expanded polystyrene (EPS) foam.

Protection Performance Breakthroughs

Through closed-cell foaming technology, PE foam demonstrates 40% enhanced cushioning performance:

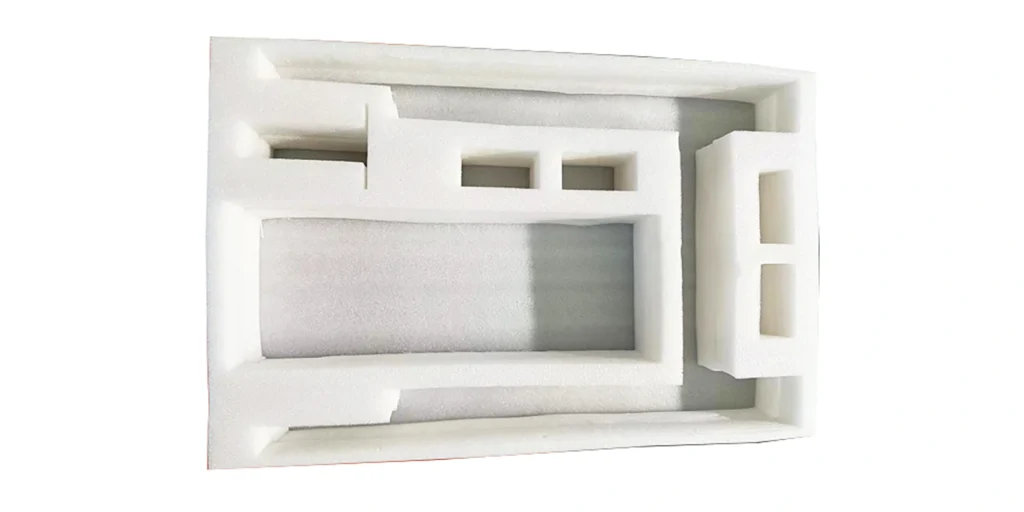

- Impact Resistance: Honeycomb structures dissipate kinetic energy uniformly for fragile electronics

- Adaptive Shock Absorption: Customizable 5mm thin-wall designs conform to product geometries

- Climate Protection: Moisture barrier properties (<0.5% water absorption) ensure cold-chain safety

Environmental Innovations

Lightweight PE foam achieves sustainability through three key advancements:

- Material Efficiency: 25% thickness reduction maintains strength while lowering carbon footprint by 18%

- Circular Recyclability: Food-grade virgin materials integrate with existing PE recycling streams (>85% recovery rate)

- Bio-based Alternatives: Sugarcane-derived ethanol enables plant-based PE with 30% biocarbon content

Market Implementation & User Insights

Leading logistics providers (SF Express, JD Logistics) report significant improvements:

- Damage rates plummet to 0.3% (vs. 2.1% for conventional packaging)

- Per-unit logistics costs reduced by ¥0.8

- 67% higher consumer satisfaction in eco-consciousness (2024 E-commerce Packaging Survey)

Future Challenges & Development Pathways

Current bottlenecks include recycled material strength degradation and sorting costs. Emerging solutions comprise:

- Nano-reinforcement: Graphene-enhanced recycled foam for improved toughness

- Smart Degradation Tags: RFID-enabled lifecycle tracking

- Policy Alignment: EU Single-Use Plastics Directive driving global standardization

FAQ

How does lightweight PE foam differ from conventional foam?

Utilizing high-expansion foaming processes, lightweight PE foam achieves 0.03g/cm³ density (vs. EPS foam’s 0.1g/cm³), delivering equivalent protection at 30% weight reduction while being fully recyclable.

Does lightweight compromise product safety?

No. Cross-linking modification yields 150kPa compressive strength (exceeding national 120kPa standards) with >95% elastic recovery, maintaining performance through 5+ reuse cycles.

What environmental value does lightweight PE foam offer?

Three core contributions:

- Material-efficient design

- Mono-material PE simplifies recycling

- Bio-based alternatives (e.g., Braskem’s sugarcane PE) reduce carbon emissions by 50%.

Proper disposal methods for used PE foam?

Closed-loop recycling involves:

- Consumer disposal in PE collection bins

- Recycling facilities granulation

- Pellet remolding (e.g., Interseroh’s 90% regeneration rate).

Ideal applications for lightweight PE foam?

Optimized for high-value fragile goods (electronics, cosmetics), precision instruments, and chilled foods. Its thermal stability (-40℃~80℃) and moisture resistance particularly benefit cross-border logistics.

WELLE Trade has over 20 years of experience in the production and processing of PE/EVA/TPE foams, so you may want to consult with them if you have any sourcing needs.