Abstract

The stringent temperature control demands of cold chain logistics have spurred innovation in insulation materials. PE Foam (Polyethylene Foam), with its exceptional thermal insulation, lightweight properties, and durability, emerges as the quintessential choice for cold chain insulation. This exposition delves into the core advantages of customized PE Foam insulation solutions, encompassing material properties, bespoke design processes, industry applications, and how tailored solutions enhance transport efficiency and cost-effectiveness—empowering businesses to elevate their cold chain logistics.

Main Text: How Custom PE Foam Services Elevate Cold Chain Efficiency

1. The Unparalleled Advantages of PE Foam

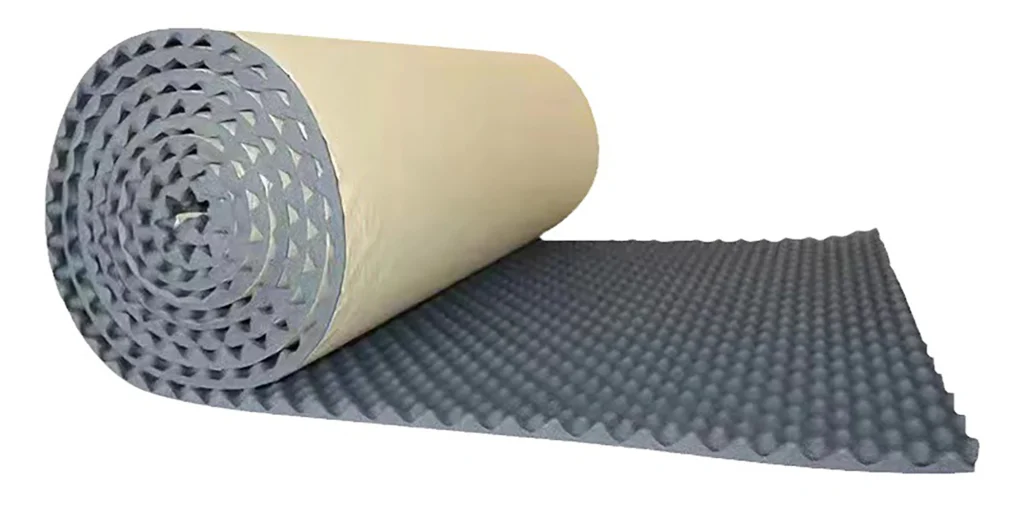

- Superior Thermal Insulation: The closed-cell structure of PE Foam effectively impedes air convection, boasting a remarkably low thermal conductivity of 0.033 W/(m·K), ensuring minimal temperature fluctuations.

- Featherweight Design: With densities ranging from 20-200 kg/m³, it lightens the load on transport equipment, reducing energy consumption and operational costs.

- Waterproof & Moisture-Resistant: Hydrophobic by nature, it thrives in high-humidity environments, preventing mold growth and structural degradation.

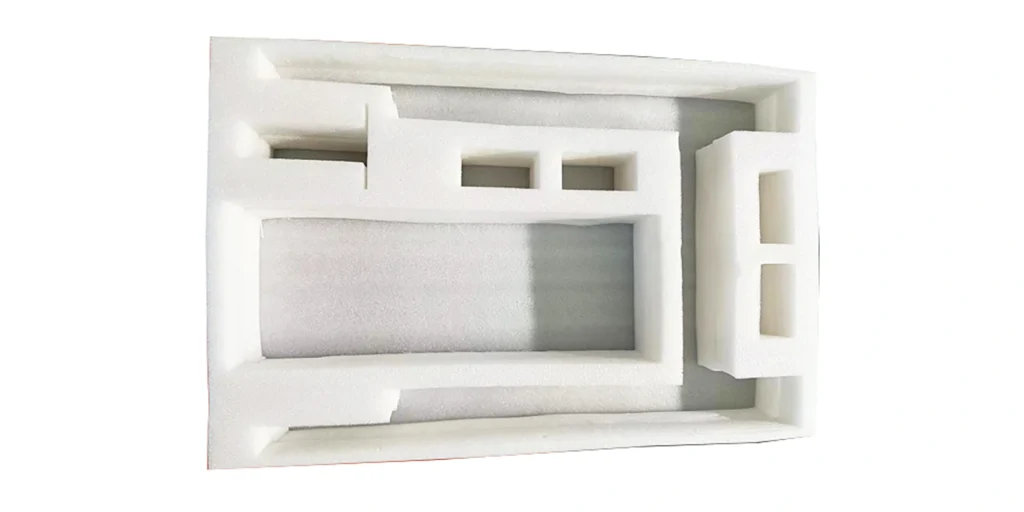

- Tailor-Made Precision: Engineered for intricate cutting and seamless conformity to packaging contours, it eliminates gaps and ensures uniform insulation.

2. The Customization Process: A Meticulous Journey

- Needs Assessment: Crafting solutions based on cargo type (perishables, pharmaceuticals, chemicals), transit duration, and temperature range (e.g., -30°C to 5°C).

- Material Selection: Curating foam density and thickness, optionally enhanced with reflective aluminum foil or composite films for optimal insulation.

- Structural Design: Utilizing 3D modeling to perfect insulation layouts for refrigerated trucks, containers, or reusable transit cases.

- Performance Validation: Conducting thermal stability tests in simulated transit environments to guarantee compliance.

3. Industry-Specific Applications

- Pharmaceutical Logistics: Vital for vaccines and biologics requiring 2-8°C precision, PE Foam ensures unwavering thermal control.

- Fresh Produce & E-Commerce: Minimizes spoilage for fruits, vegetables, and frozen meats, extending shelf life.

- Industrial Cold Chain: Shields chemicals and sensitive instruments from condensation and external temperature shifts.

4. Four Compelling Reasons to Choose Customization

- Cost Efficiency: Bespoke designs minimize material waste, offering long-term savings over generic solutions.

- Regulatory Assurance: Compliant with GSP (pharmaceuticals) and HACCP (food) standards, mitigating supply chain risks.

- Eco-Consciousness: Fully recyclable, aligning with sustainable logistics practices.

- Agile Responsiveness: Supports rapid prototyping and small-batch trials for urgent demands.

FAQ: Expert Insights

Q1: How does PE Foam compare to alternatives like polyurethane or EPS foam?

A: PE Foam excels in compression resistance, waterproofing, and flexibility. While polyurethane offers higher insulation at greater cost, EPS is brittle and less eco-friendly.

Q2: What is the typical lead time for custom PE Foam insulation?

A: Standard timelines span 7-15 days (design, prototyping, and testing), with expedited services available (3-5 days).

Q3: How are thickness and density determined?

A: Thermodynamic analysis of temperature differentials, cargo sensitivity, and equipment specifications informs optimal parameters.

Q4: Is PE Foam environmentally sustainable? Can it be reused?

A: Food-grade/medical-grade variants are non-toxic and reusable after sterilization, with a recycling rate exceeding 90%.

Q5: Are customized solutions cost-prohibitive?

A: Initial costs may marginally exceed generic options, but reduced product loss (15%-30%) ensures superior ROI.

WELLE Trade has over 20 years of experience in the production and processing of PE/EVA/TPE foams, so you may want to consult with them if you have any sourcing needs.