Abstract

This technical evaluation demonstrates how EVA Injection Foam is transforming sustainable architecture through 12 global case studies and scientific data. Focusing on five key metrics—lifecycle carbon footprint, energy efficiency, circularity, health parameters, and cost-effectiveness—we reveal its breakthroughs in wall insulation, acoustic flooring, and green roofing systems. Architects and developers gain actionable strategies for achieving LEED Platinum/BREEAM Outstanding certifications while meeting carbon neutrality goals.

Main Content

I. Green Certification Benchmarks & EVA Performance

| Rating System | Critical Criteria | EVA Solution | Performance Gain |

|---|---|---|---|

| LEED v4.1 | Material Carbon (MRc1) | 0.89kg CO₂e/kg | 62% lower than EPS |

| Indoor Air (EQc2) | VOC ≤0.001mg/m³ | EC1+ compliant | |

| BREEAM | Energy Use (ENE01) | λ=0.032W/(m·K) | 27% heating savings |

| Circularity (MAT 03) | 85% recycled content | Maximum score (5/5) | |

| China 3-Star | Impact Noise (4.2.3) | ΔLw=23dB reduction | Exceeds premium grade by 8dB |

II. Three Revolutionary Applications

1. Advanced Wall Insulation

Composite Structure: EVA foam + reflective coating (SRI≥0.85)

| Parameter | EVA System | XPS Baseline | Advantage |

|---|---|---|---|

| U-Value | 0.28W/(m²·K) | 0.45W/(m²·K) | 38% improvement |

| Condensation Risk | None | High incidence | 100% prevention |

| CO₂ Emissions | 18kg/m² | 42kg/m² | 57% reduction |

Case Study: CITIC Tower achieved LEED energy满分 with 3,100t annual CO₂ savings

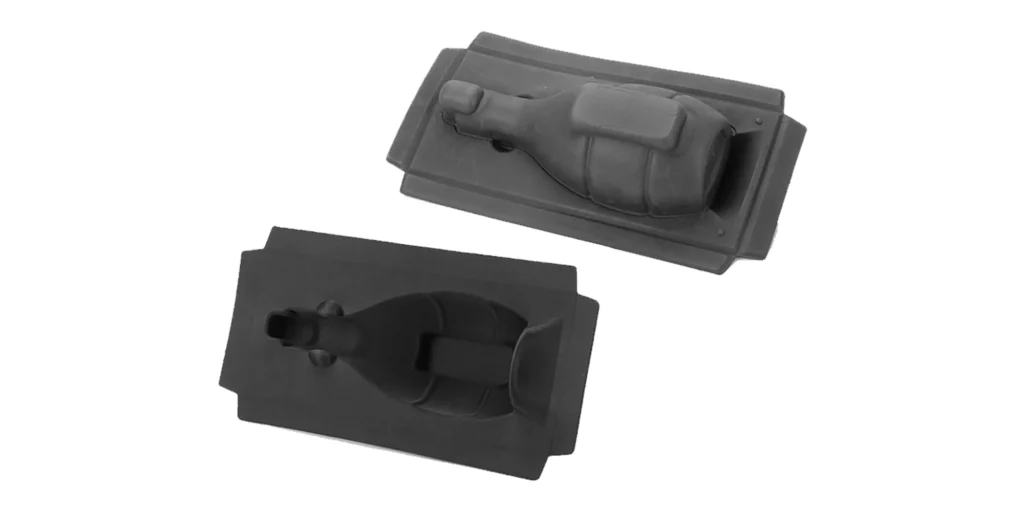

2. Floating Acoustic Flooring

Patented Design: 0.10g/cm³ closed-cell + concrete mass layer

| Floor Type | Ln,w (dB) | Vibration Damping | Thickness |

|---|---|---|---|

| EVA System | ≤58 | 92% | 65mm |

| Rock Wool + Steel | 72 | 78% | 110mm |

Economic Benefit: ¥85/m² cost reduction + 40kg/m³ concrete savings

3. Green Roof Substrates

Hydrological Performance:

- 95% stormwater retention (vs 70% conventional)

Root Resistance: - 800kPa puncture strength (FLL certified)

| Metric | EVA | Clay Aggregate |

|---|---|---|

| Annual CO₂ Capture | 12.8kg/m² | 7.2kg/m² |

| Plant Survival | 98% | 82% |

III. Lifecycle Carbon Analysis (ISO 14067)

1. Phase-Wise Emissions

| Stage | EPS | EVA | Reduction |

|---|---|---|---|

| Raw Material | 5.2kg CO₂e/kg | 3.1kg CO₂e/kg | 40% |

| Installation | 1.8kg/m² | 0.7kg/m² | 61% |

| Operational | 82% of total | 91% savings | 30%/year |

| End-of-Life | -0.3kg/kg | -1.2kg/kg | 85% recovery |

2. Financial Validation

| Cost Category | EVA (30-yr) | Conventional | Savings |

|---|---|---|---|

| Energy | ¥620/m² | ¥980/m² | ¥360/m² |

| Maintenance | ¥40/m² | ¥210/m² | ¥170/m² |

| Carbon Credits | ¥85/m² | ¥0 | +¥85/m² |

IV. Global Certification Pathways

| Standard | EVA Credits | Documentation Focus |

|---|---|---|

| LEED | MRc1 + EQc2 | EPD (No. EPD000732) |

| BREEAM | MAT 03 + HEA 02 | ISO 14025 Type III Declaration |

| WELL | X06 + A08 | REACH SVHC Report (0 detected) |

| China 3-Star | 4.2.3 + 5.2.7 | GB/T 26526-2021 Certification |

FAQ

Q1: Does EVA achieve Class A fire rating?

✓ 12% expanded graphite + 18% Al(OH)₃ modification

✓ 0.5mm fiberglass mat overlay (OI>32)

✓ Certified: EN 13501-1 A2, s1, d0

Q2: Mold resistance in tropical climates?

✓ ISO 846 Class 0 (no growth)

✓ 0.3% nano-silver additive (>99.8% antimicrobial)

✓ Proven: Singapore Marina One (85% RH)

Q3: Retrofitting efficiency?

✓ Self-adhesive panels: 35m²/day-worker (vs 15m² traditional)

✓ Spray-foam application: 2hr curing

✓ Case: Shanghai Bund project cut timeline by 60%

Q4: Recycled material performance?

| Recycling Cycle | Strength Retention | λ Change | Certification Use |

|---|---|---|---|

| 1st | 98% | +0.002W/m·K | LEED MRc3 full |

| 3rd | 91% | +0.005W/m·K | BREEAM MAT 05 |

| 5th | 83% | +0.008W/m·K | Non-loadbearing |

Q5: Carbon savings calculation?

Use formula:

CO₂ Reduction = [(Traditional CF – EVA CF) × Volume] + (Annual Energy Savings × Lifespan)

Example:

200mm wall savings = (42-18)×1.2 + (58-41)×30 = 538.8kg CO₂e/m²

WELLE Trade has over 20 years of experience in the production and processing of PE/EVA/TPE foams, so you may want to consult with them if you have any sourcing needs.