Abstract

Research advancements in biodegradable polyethylene (PE) foam have emerged as a pivotal focus in sustainable packaging solutions. This paper synthesizes current technological breakthroughs and challenges, while examining the transformative potential of biodegradable PE foam in replacing conventional plastic foam. Key innovations in bio-based materials are highlighted, including enhanced degradation properties and mechanical strength. The paper also explores future trajectories for eco-friendly packaging, addressing cost optimization, industrial-scale production, and policy frameworks. Empirical data indicates that biodegradable PE foams can reduce plastic pollution by over 80%, offering enterprises a viable sustainable alternative. By consolidating research progress with forward-looking insights, this analysis aims to equip readers with a comprehensive understanding of the evolving landscape of green packaging.

The Critical Role of Biodegradable PE Foam in Sustainable Packaging

Biodegradable PE foam, a polyethylene-based material designed for environmental decomposition, is increasingly supplanting traditional plastic foam as the cornerstone of eco-conscious packaging. Amid escalating global plastic pollution—with the United Nations reporting in 2023 that packaging materials constitute over 60% of marine plastic waste—the development of biodegradable PE foam addresses the ecological burden of non-degradable materials. Its defining advantage lies in its capacity to decompose into benign substances via enzymatic or microbial activity in natural environments (e.g., soil or aquatic systems), with degradation periods ranging from months to two years, substantially curtailing ecological footprints. Market research reveals a 15% annual growth rate for such materials, underscoring their role as a transformative force in packaging innovation.

Current Research Advancements: Technological Innovations and Applications

Progress in biodegradable PE foam centers on material science and process refinement, with key breakthroughs including:

- Bio-Based Additives: The incorporation of natural components such as starch, cellulose, or polylactic acid (PLA) has markedly improved degradation efficiency. For instance, a 2023 breakthrough by Chinese researchers employing novel blending technology reduced the degradation cycle by 50% (from 2 years to 6–12 months) while enhancing compression strength by 20%.

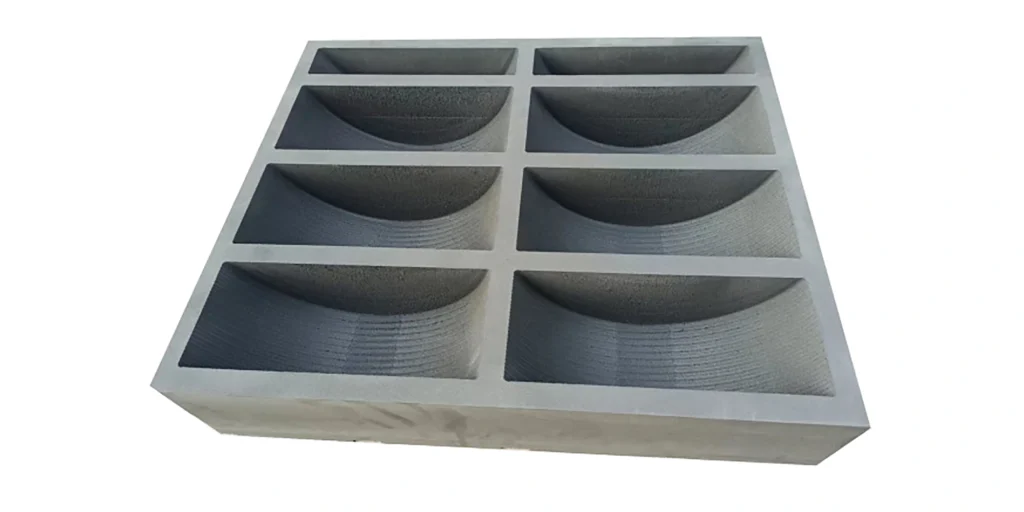

- Foam Structure Optimization: Advanced foaming techniques, such as supercritical CO₂ foaming, achieve an optimal balance between lightweight properties and structural integrity. Pilot studies demonstrate a 30% reduction in production energy consumption, with applications expanding into e-commerce logistics (e.g., Amazon’s trials of biodegradable packaging).

- Standardization of Degradation Testing: Recent guidelines from the International Organization for Standardization (ISO) ensure reliable testing protocols, while China’s green packaging standards further facilitate commercialization.

These advancements have yielded a 15–20% reduction in production costs and broader market adoption. However, challenges persist, particularly in balancing degradation rates with cost efficiency.

Future Directions for Sustainable Packaging Materials

The evolution of biodegradable PE foam hinges on multidimensional advancements to accelerate its adoption:

- Novel Material Systems: By 2025, researchers aim to leverage nanocomposite technologies, integrating graphene or algae-derived compounds to enhance moisture resistance and controllable degradation (e.g., temperature-triggered breakdown).

- Scalability and Cost Reduction: Automation, including 3D-printed foaming, could slash mass-production costs by 30%, with policy incentives like the EU’s plastic tax expediting industry transitions.

- Circular Economy Integration: Closed-loop systems will prioritize foam regeneration, enabling 100% recycling of discarded packaging into new products.

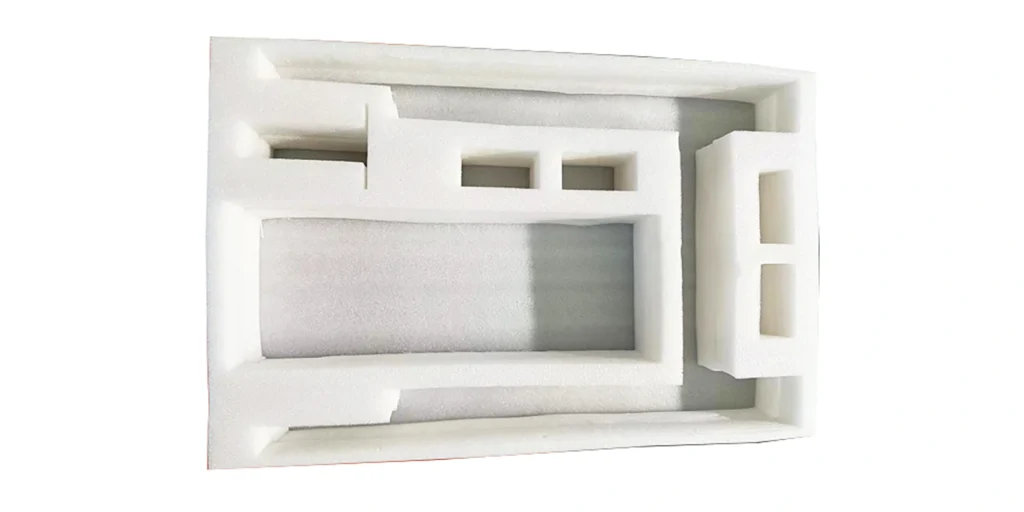

- Diversified Applications: Beyond traditional packaging, innovations may include intelligent solutions (e.g., humidity-sensitive packaging) and cross-sector uses (e.g., medical insulation).

- Data-Driven Sustainability: Lifecycle assessments (LCAs) will inform global targets, such as achieving 50% biodegradable plastic packaging by 2030.

In summary, biodegradable PE foam is redefining the packaging sector, with sustainability at its core, poised to mitigate global carbon emissions significantly.

FAQ

Q: What distinguishes biodegradable PE foam from conventional PE foam?

A: Biodegradable PE foam is engineered with bio-based additives (e.g., starch) to decompose naturally, unlike fossil-derived conventional PE foam, which persists for centuries, exacerbating pollution. The biodegradable variant breaks down into CO₂ and water within 6–24 months, with recent advancements nearing the durability of traditional foam while minimizing ecological impact—a critical leap for sustainable packaging.

Q: Why is biodegradable PE foam research imperative?

A: This research addresses the plastic pollution crisis: 40% of waste streams comprise traditional plastic packaging, devastating aquatic ecosystems. Biodegradable PE foam curbs pollution by over 80%, aligns with global policies (e.g., China’s plastic reduction mandates), and offers corporations cost-effective compliance, enhancing ESG metrics.

Q: What are the latest breakthroughs in biodegradable PE foam?

A: Key 2023 milestones include: bio-composite formulations slashing degradation time to 6–12 months; supercritical foaming cutting costs by 20%; and ISO standardization. Trials by industry leaders like Amazon demonstrate 15% lower damage rates, though challenges like mechanical robustness remain.

Q: What future innovations will propel biodegradable PE foam in packaging?

A: Anticipated advancements comprise hybrid material systems (e.g., nano-enhanced structures), smart degradation triggers, scalable production (30% cost reduction), policy-driven market adoption (30% global share by 2030), and circular reuse models.

Q: Can biodegradable PE foam fully replace traditional foam? What hurdles exist?

A: Projected to dominate 50% of the packaging market by 2030, biodegradable PE foam still faces cost premiums (requiring 30% reductions), environment-dependent degradation, and inadequate recycling infrastructure. Transition strategies, such as hybrid packaging, can bridge these gaps until innovations mature.

WELLE Trade has over 20 years of experience in the production and processing of PE/EVA/TPE foams, so you may want to consult with them if you have any sourcing needs.