Abstract

The exponential growth in global electronic product transportation and heightened consumer safety expectations have positioned PE Foam (polyethylene foam) as a leading shock-absorbing packaging solution. Known for its cushioning, lightweight properties, and customization, this material dominates electronics packaging. This study explores market dynamics, technological innovations, sustainability, and cost efficiency, revealing a $4.2 billion global market (2023) with a 6.8% CAGR—electronics account for 35% of usage. Environmental regulations and biodegradable breakthroughs drive sustainability.

Market Drivers Analysis

Miniaturization & Precision of Electronics

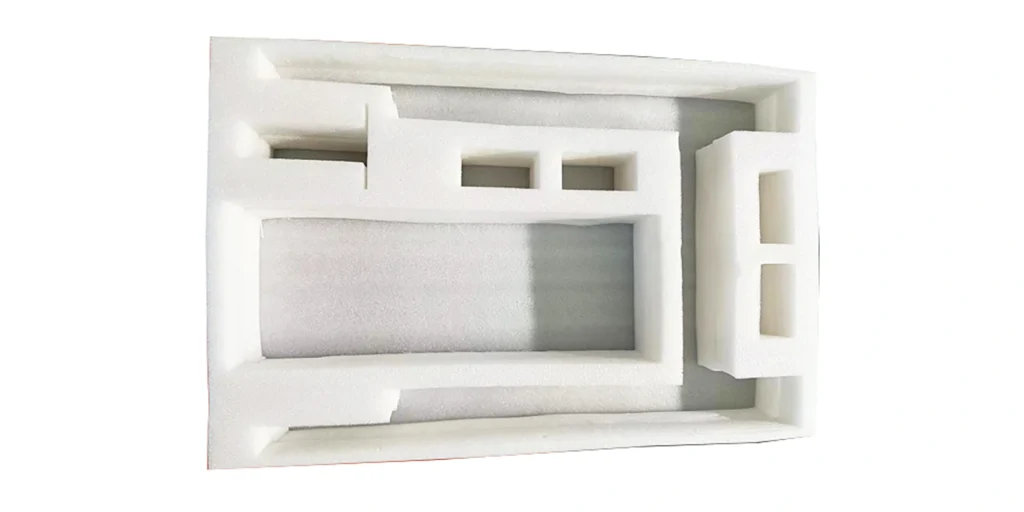

- Compact devices (smartphones, AR/VR, foldables) demand shock-resistant packaging.

- PE Foam’s adjustable density (20-200kg/m³) reduces shipping damage by 42% (TWS earphone case study).

E-Commerce & Global Logistics Expansion

- Cross-border e-commerce ($627B in 2023) requires ISTA 3A-compliant packaging.

- PE Foam’s die-cutting adaptability suits platforms like Amazon and AliExpress.

Technological Advancements

Eco-Conscious Solutions

- Biodegradable PE Foam: Starch/PLA blends decompose in 3-5 years vs. centuries for conventional PE.

- Recycled PE: 30-50% recycled content meets ASTM D4169 at 18% lower cost.

- Regulations: EU’s PPWR mandates 30% recycled content by 2030.

Advanced Composite Structures

- Multi-layer hybrids (EPE/EVA): 50% higher compressive strength.

- Surface coatings: Anti-static (≤10⁹Ω) and flame-retardant (UL94 V-0) for sensitive electronics.

Industry Challenges & Responses

Sustainability-Cost Paradox

- Recycled PE costs drop but lag in elasticity; microcellular foaming optimizes performance.

Competitive Landscape

- Pulp molding/air cushions grow in low-end markets, but PE Foam remains critical for premium electronics (70%+ energy absorption).

FAQ

Q1: How does PE Foam surpass EPE/EPS?

- 20-30% better impact resistance vs. EPE; recyclable (unlike brittle EPS).

Q2: Does biodegradable PE Foam compromise protection?

- 85% compressive strength vs. virgin material; struggles in extreme cold (-40°C).

Q3: Cost-reduction strategies?

- Honeycomb designs cut material use.

- Regional manufacturing (e.g., Southeast Asia) reduces logistics costs.

Q4: Key certifications?

- Safety: RoHS, REACH.

- Performance: ISTA 3A, ASTM D1596.

WELLE Trade has over 20 years of experience in the production and processing of PE/EVA/TPE foams, so you may want to consult with them if you have any sourcing needs.