Abstract

With the automotive industry’s increasing demand for lightweight, eco-friendly, and comfort-enhancing solutions, PE Foam (Polyethylene Foam) has emerged as a pivotal material in automotive interior manufacturing due to its unique physical properties and processing advantages. This article systematically examines the technical merits of PE Foam in automotive interior processing across four key dimensions—material characteristics, process efficiency, environmental value, and cost-effectiveness—while addressing common industry inquiries to provide manufacturers with informed material selection guidance.

1. Core Technical Advantages of PE Foam

1. Lightweight Without Compromising Structural Integrity

- Ultra-Low Density & Weight: With a density of merely 0.03–0.3 g/cm³, PE Foam is 30–50% lighter than conventional materials (e.g., PU foam), contributing to vehicle weight reduction and energy efficiency.

- Superior Impact Resistance: Its closed-cell structure delivers exceptional energy absorption, enhancing collision resilience and prolonging component lifespan.

2. Efficient and Adaptive Processing

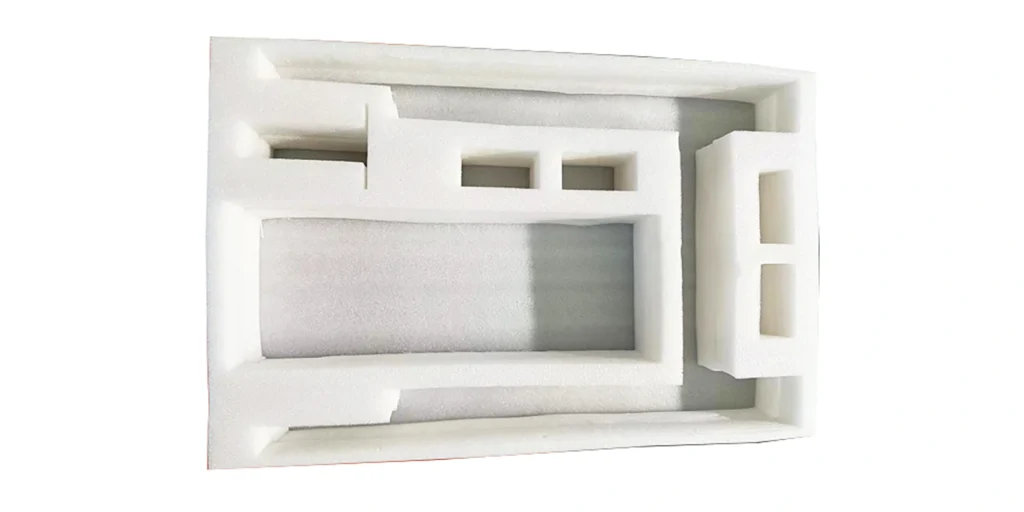

- Versatile Molding Capabilities: Compatible with both thermoforming and cold-pressing techniques, PE Foam enables rapid production of intricate contoured parts (e.g., door panel liners, dashboard padding) to accommodate diverse design requirements.

- Precision Cutting Technology: Laser/CNC cutting ensures minimal material waste and supports bespoke production.

3. Eco-Conscious and Safety-Optimized

- Low VOC Emissions: Compliant with stringent automotive environmental standards (e.g., ELV, REACH), it mitigates interior air pollution risks.

- Exceptional Flame Retardancy: Certified under UL94-HB, it significantly elevates fire safety.

4. Cost-Effectiveness

- Stable Raw Material Supply: Abundant polyethylene resin availability ensures price stability, reducing supply chain volatility.

- High Production Efficiency: Short成型cycles (30–60 seconds per piece) and low-energy processes yield a 20–35% reduction in overall costs.

2. Key Applications in Automotive Interiors

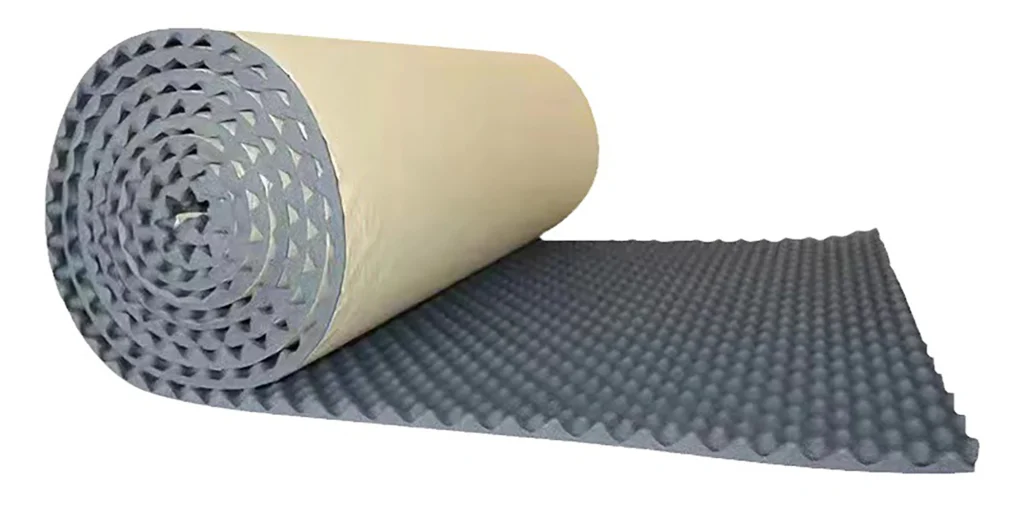

- Noise Insulation: Door panels and headliners utilize PE Foam to dampen high-frequency noise, optimizing NVH performance.

- Cushioning & Support: Seat backs and headrest fillings balance comfort with structural reinforcement.

- Thermal Barriers: Engine compartment heat shields (e.g., under-dashboard insulation) effectively block heat transfer.

3. FAQ: Addressing Industry Queries

Q1: How does PE Foam compare to EPP (Expanded Polypropylene Foam)?

- Material Properties: PE Foam excels in flexibility for elastic deformation applications, while EPP offers higher rigidity for structural support.

- Cost Efficiency: PE’s lower raw material cost makes it ideal for high-volume production.

Q2: How to prevent deformation during processing?

- Optimize Mold Parameters: Maintain temperatures at 80–120°C and control pressure duration to prevent heat-induced shrinkage.

- Implement Gradual Cooling: Phased cooling stabilizes internal microstructure.

Q3: Is PE Foam recyclable?

- Yes. Closed-loop recycling via melt reprocessing is feasible, with some manufacturers achieving >30% recycled content integration.

Q4: Is it suitable for electric vehicles (EVs)?

- Absolutely. Its lightweight properties extend battery range, and its non-interference with electromagnetic systems aligns with EV safety protocols.

Q5: How to enhance PE Foam’s acoustic performance?

- Multilayer Composite Design: Combining PE Foam with non-woven fabrics targets broadband noise attenuation.

- Adjust Foaming Ratio: Tailoring pore size optimizes soundwave dispersion.

WELLE Trade has over 20 years of experience in the production and processing of PE/EVA/TPE foams, so you may want to consult with them if you have any sourcing needs.