Abstract

Polyethylene foam (PE Foam), distinguished by its lightweight properties, high elasticity, shock absorption, and corrosion resistance, has emerged as an optimal solution for protective packaging across diverse industries. This paper explores its innovative applications in four key sectors—consumer electronics, medical devices, automotive manufacturing, and furniture logistics—through real-world case studies, while outlining its technical advantages and market potential.

Industry Application Case Studies

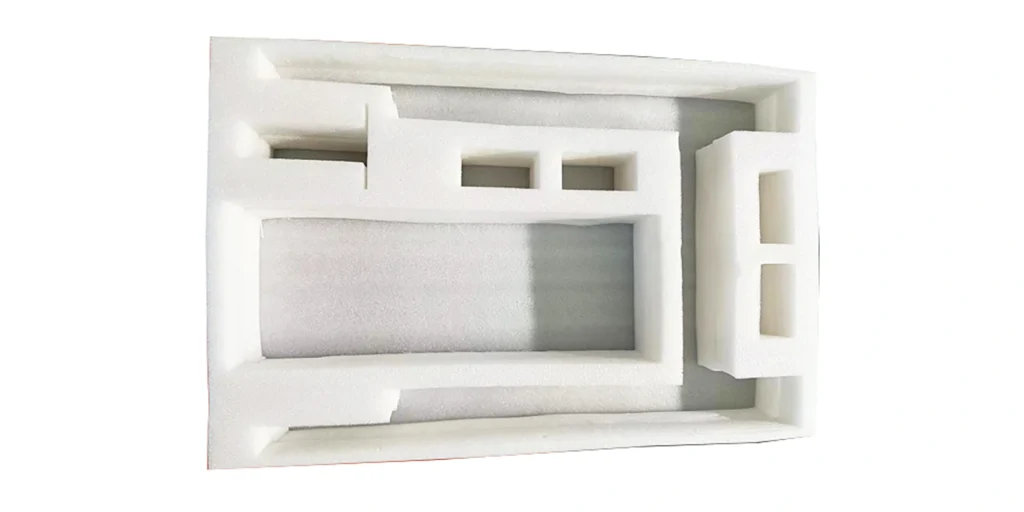

1. Consumer Electronics: The Invisible Guardian of Precision Instruments

Case Study: A global smartphone brand employs custom-engineered PE Foam inserts seamlessly integrated into packaging walls, achieving “zero damage” during transit. With tailored density ranges (25–45 kg/m³), the foam precisely accommodates varying product weights, while its anti-static treatment safeguards sensitive components from electrostatic interference.

2. Medical Devices: Dual Assurance of Safety and Hygiene

Case Study: A high-end medical equipment manufacturer utilizes antimicrobial PE Foam as transport liners for CT scanner components. Certified under ISO 10993 for biocompatibility and enhanced with bacteria-inhibiting properties, the material meets stringent sterile-environment requirements while reducing medical waste costs through reusability.

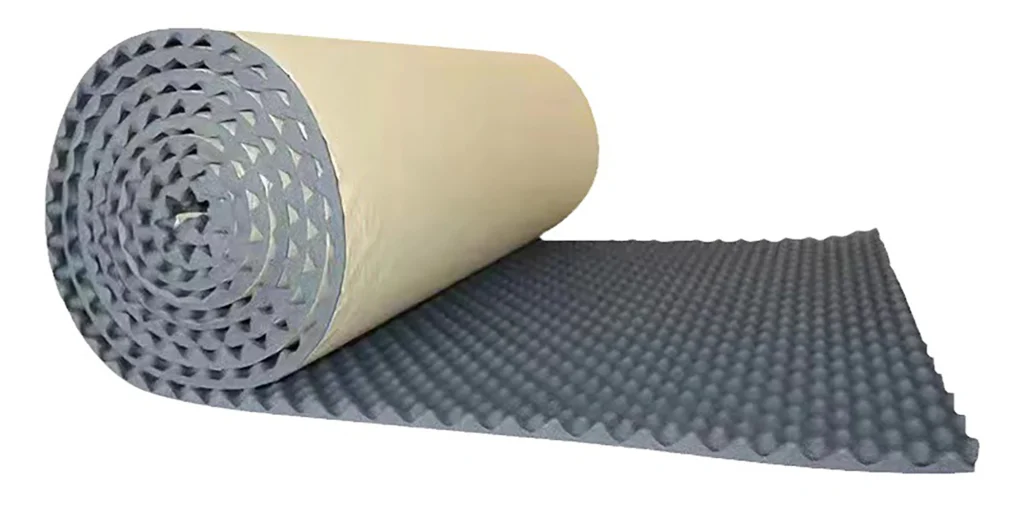

3. Automotive Manufacturing: Harmonizing Lightweight Design with NVH Performance

Case Study: Closed-cell PE Foam serves as an impact-absorbing layer in electric vehicle battery packs, demonstrating over 30% shock energy dissipation in crash tests. Its low density (15–30 kg/m³) aligns with the industry’s lightweighting objectives without compromising safety.

4. Furniture Logistics: Cost-Efficient Customization

Case Study: An e-commerce furniture platform adopts laser-cut PE Foam modules for irregularly shaped items (e.g., curved sofas, glass coffee tables), delivering seamless “single-piece” packaging. This innovation slashed shipping damage rates from 8% to 0.5% and reduced labor costs by 40%.

FAQ

Q1: How does PE Foam outperform EPS (Expanded Polystyrene)?

A: PE Foam excels in compressive strength (2–3× higher than EPS), flexibility (180° bend-resistant), and sustainability (>90% recyclability). Unlike EPS, it eliminates static-induced particle adhesion, making it ideal for precision instrument packaging.

Q2: How to select the optimal PE Foam density?

A: Density selection aligns with load-bearing requirements:

- Low density (15–25 kg/m³): Fragile items (eyeglasses, small electronics)

- Medium density (25–40 kg/m³): Consumer electronics, instrumentation

- High density (40–60 kg/m³): Industrial machinery, automotive parts

Q3: Is PE Foam stable under extreme temperatures?

A: Premium PE Foam maintains performance between -60°C to +100°C. Flame-retardant variants (e.g., UL94 HF-1 certified) meet stringent requirements for lithium battery transport.

Q4: Are eco-degradable options available?

A: While conventional PE Foam relies on physical recycling, bio-based alternatives (30% sugarcane fiber) now offer 3–5 year degradation cycles, certified by TUV for biodegradability.

Q5: Are custom PE Foam molds cost-prohibitive?

A: Digital solutions (3D scanning + CNC machining) enable low-volume orders with mold costs at ~$1,000 and 3–5 day lead times, catering to SMEs’ agile production needs.

WELLE Trade has over 20 years of experience in the production and processing of PE/EVA/TPE foams, so you may want to consult with them if you have any sourcing needs.