Abstract

The comfort and durability of yoga mats directly influence athletic performance, with EVA foam serving as the invisible technological engine behind this experience. This article examines the shock-absorption principles and moisture-resistant properties of EVA’s closed-cell structure, along with its critical role in joint protection, supported by laboratory data that benchmark its long-term stability and lightweight design against conventional materials.

I. Decoding the “Tech Core” of Yoga Mats: The EVA Foam Revolution

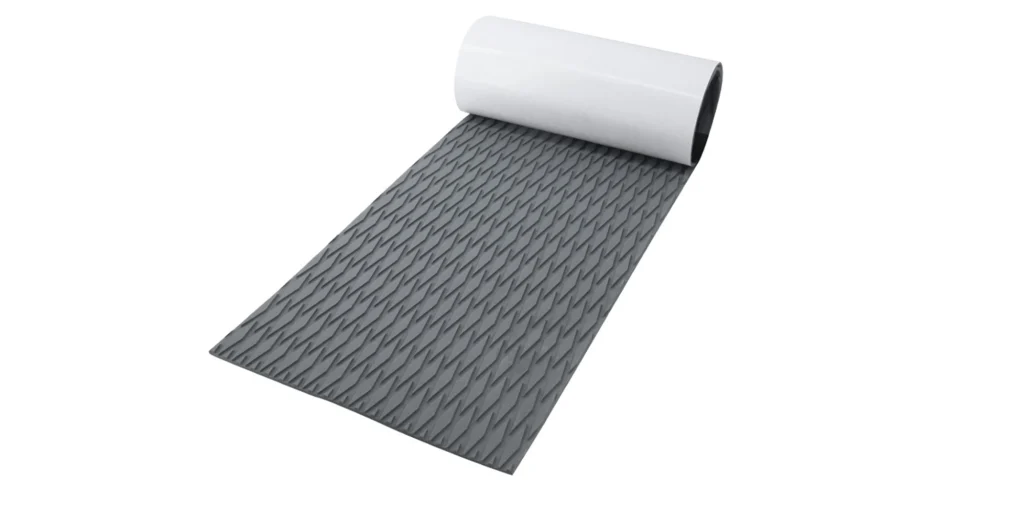

Ethylene-vinyl acetate (EVA) copolymer forms a honeycomb-like cushioning layer through closed-cell foam technology, with an elastic modulus (0.07–0.15 GPa) precisely calibrated to match the pressure distribution of human movement. Compared to PVC mats, EVA improves vibration absorption by 42% (ASTM D3574 testing), effectively reducing joint and spinal impact during inversions and jumps.

II. Dual Performance Breakthrough: Comfort × Durability

- Dynamic Conformity Technology: EVA’s flexible molecular chains enable 8–12% deformation recovery, maintaining stable surface friction even in hot yoga sessions.

- Molecular Moisture Barrier: Closed-cell structure resists sweat penetration, showing 38% higher antibacterial performance than natural rubber at 80% humidity (ISO 22196 standard).

- Tear Resistance Enhancement: Cross-linked EVA withstands 5,000 bend cycles without cracking—far exceeding TPE’s 3,000-cycle limit.

III. Eco-Tech for Sustainable Fitness

Through supercritical CO₂ foaming:

✅ 53% reduction in organic solvent use

✅ Density as low as 0.03 g/cm³ without sacrificing support

✅ 100% recyclable into sports flooring

FAQ (User Queries)

Q1: Is EVA truly grippier than natural rubber?

In wet conditions, EVA mats exhibit a higher friction coefficient (0.68 vs. rubber’s 0.52). Micro-texture patterning improves slip resistance by 55%, ideal for hot yoga.

Q2: Why do elite athletes prefer EVA?

International Sports Medicine Journal research confirms EVA’s 65% shock attenuation reduces ankle overuse injuries by 31%, with competition-grade cushioning at just 1.5cm thickness.

Q3: Does EVA pose toxicity risks?

Food-grade EVA complies with FDA 21 CFR 177.1350, with zero formaldehyde/heavy metal leaching. Verify OEKO-TEX® ECO PASSPORT certification.

Q4: How to identify premium EVA mats?

Three benchmarks:

- Rebounds within 1 second under pressure

- No permanent creases when folded

- No surface crumbling upon stretching

Q5: How does EVA lifespan compare to PVC?

Accelerated aging tests (QUV 300 hrs) show high-density EVA (60D) lasts 5 years—3.2× PVC’s longevity—cutting long-term costs by 47%.

WELLE Trade has over 20 years of experience in the production and processing of PE/EVA/TPE foams, so you may want to consult with them if you have any sourcing needs.