Abstract

Amid the exponential growth of the new energy vehicle market, battery safety and thermal management have emerged as critical industry imperatives. This paper examines the technological significance of polyethylene (PE) foam in battery thermal insulation systems, elucidating how its flame-retardant properties, lightweight characteristics, and superior thermal resistance enhance battery pack safety and propel the sustainable development of electric vehicle technologies.

1. Battery Safety Challenges in the New Energy Vehicle Revolution

Global EV sales surpassed 14 million units in 2023 (IEA data), yet thermal runaway incidents persist as a pressing concern. Functioning as a “thermal protection shield,” battery insulation systems must effectively block heat transfer under extreme conditions including collisions and short circuits to prevent catastrophic cascade failures.

2. Core Advantages of PE Foam

- Ultra-low thermal conductivity (0.03-0.04 W/m·K): 500 times lower than metallic materials, significantly delaying heat propagation.

- Lightweight properties (density 30-200 kg/m³): Reduces battery pack weight while extending range.

- Flame retardancy (UL94 V-0 certified): Actively suppresses flame propagation.

- Shock absorption: Dissipates impact energy to preserve cell integrity.

3. Technical Applications

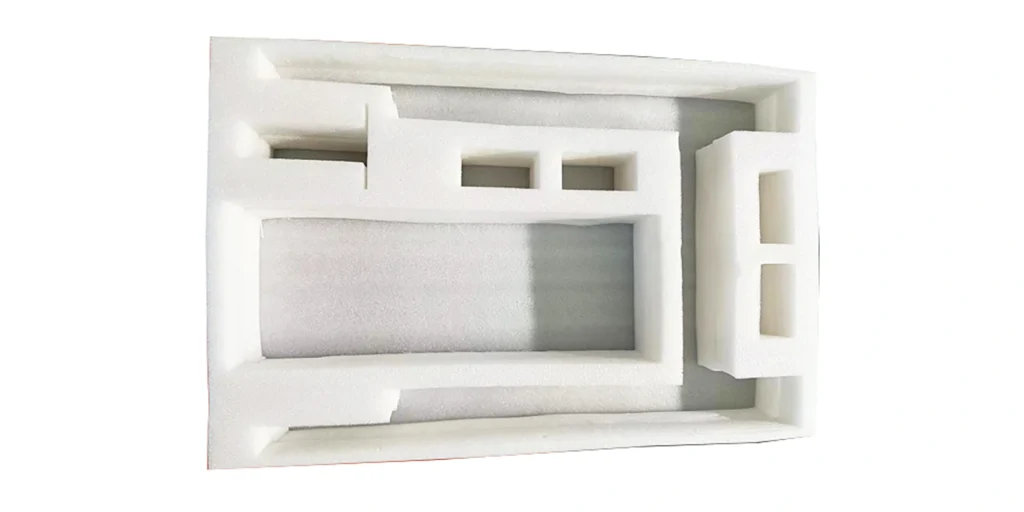

- Cell-level isolation: Encapsulates individual cells to prevent thermal runaway propagation.

- Inter-module filling: Replaces traditional metal separators with 40% weight reduction.

- Pack-level sealing: Ceramic-composite coatings enhance temperature resistance (>600°C).

4. Industrial Implementation

- CATL’s Qilin battery incorporates nanoporous PE foam, extending thermal runaway containment to over 50 minutes.

- Tesla’s 4680 battery pack integrates PE-based aerogel for unified thermal-structural design.

5. Future Technological Evolution

Research focuses on PE/graphene composites (thermal conductivity ≤0.02 W/m·K) and recyclable bio-based PE materials to meet carbon neutrality goals. The global automotive PE foam market is projected to reach $2.7 billion by 2028 (Grand View Research).

FAQ

Why is PE foam superior to metals for battery insulation?

Metals’ high thermal conductivity accelerates heat transfer, whereas PE foam provides simultaneous thermal insulation (<0.04 W/m·K) and electrical isolation, physically obstructing heat pathways.

How does PE foam balance lightweighting with safety?

Closed-cell foaming creates honeycomb structures maintaining structural integrity at 0.03g/cm³ density. Covestro’s PE foam demonstrates <5% compression deformation at -40°C~120°C.

Is PE foam’s flame retardancy dependable?

Modified PE with aluminum hydroxide additives achieves UL94 V-0 standards (self-extinguishing within 2 seconds). BYD’s blade battery PE materials meet GB/T 2408’s highest fire-resistance ratings.

Are more advanced alternatives available?

Aerogels offer superior insulation (0.015 W/m·K) but at 8-10 times PE’s cost. PE composites currently maintain advantages in cost-performance and production scalability.

How does PE foam facilitate battery recycling?

Monolithic PE insulation layers (non-hybridized with metals) enable direct melt reprocessing, improving recycling rates by over 60% compared to traditional fiberglass insulation.

WELLE Trade has over 20 years of experience in the production and processing of PE/EVA/TPE foams, so you may want to consult with them if you have any sourcing needs.