Abstract

In residential settings, noise pollution frequently compromises quality of life. While conventional soundproofing materials prove costly and installation-intensive, polyethylene (PE) foam emerges as an ideal solution—combining lightweight properties, high elasticity, affordability, and exceptional acoustic performance. This paper examines PE foam’s advantages in soundproof wall panel applications, demonstrating its cost-effective approach to acoustic optimization while addressing common queries through practical FAQs.

Material Properties and Acoustic Principles

PE foam, characterized by closed-cell structures, exhibits remarkable cushioning and sound-absorption capabilities. Its noise reduction mechanism operates through dual pathways:

Sound wave absorption: The porous matrix effectively dissipates mid-to-high frequency noise (e.g., vocal ranges, electronic devices) by minimizing sound wave reflection.

Vibration dampening: The material significantly reduces structure-borne noise transmission (e.g., footsteps, appliance vibrations), particularly for low-frequency disturbances.

Compared with traditional materials (gypsum boards, mineral wool panels), PE foam offers:

- Superior cost efficiency (typically 30-40% savings)

- Simplified customization

- DIY-friendly installation

Budget-Conscious Implementation Methods

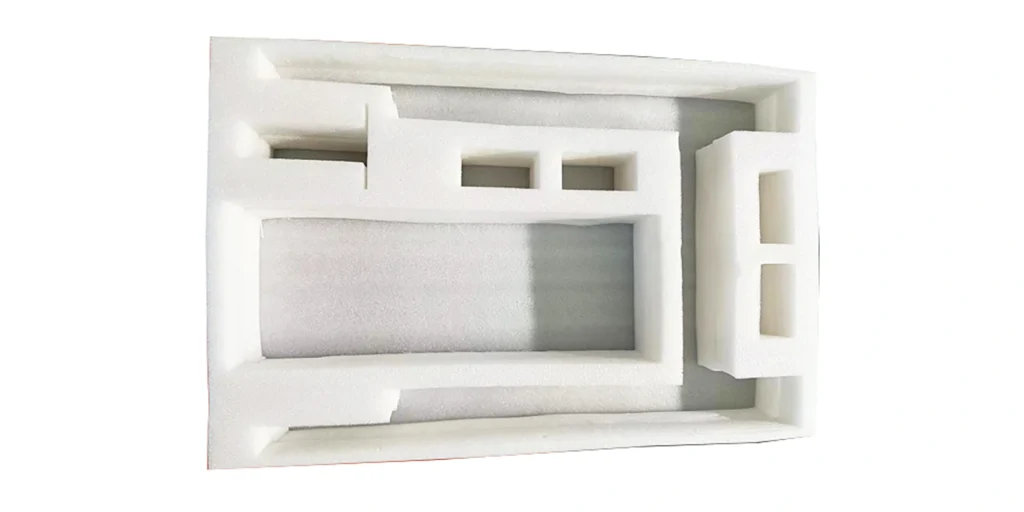

Adhesive-mounted panels: Direct application onto walls/ceilings using pressure-sensitive adhesives, ideal for rental properties or temporary solutions.

Composite acoustic walls: Layering PE foam beneath gypsum or decorative panels enhances STC (Sound Transmission Class) ratings while maintaining aesthetics.

Perimeter sealing: Custom-cut foam strips eliminate noise leakage through door/window gaps.

These solutions demonstrate 50-70% cost reduction versus professional soundproofing projects.

Optimization Strategies

Material synergy: Combining with mass-loaded vinyl or polyester fiber improves low-frequency performance (+3-5dB reduction).

Safety considerations: Flame-retardant PE-EVA composites (UL94 standards recommended) should supersede conventional variants.

Aesthetic integration: Decorative fabric overlays or paintable surfaces preserve interior design coherence.

FAQ

Q1: Does PE foam provide absolute sound isolation?

A: While eliminating 100% of noise transmission proves unattainable, PE foam achieves 70-85% reduction for conversational frequencies (500-4000Hz). Low-frequency impacts require supplementary damping materials.

Q2: Does installation significantly reduce room dimensions?

A: Standard 3mm-10mm panels add negligible space (≤1% volumetric loss). Composite systems may require 25-50mm wall thickness augmentation.

Q3: Are flammability concerns justified?

A: Standard PE foam exhibits moderate combustibility (HB rating). Opt for fire-retardant grades (V0/V1 classifications) with >32% oxygen index for residential safety compliance.

Q4: What technical skills are required for DIY installation?

A: Basic household tools (utility knives, measuring tapes) coupled with acrylic adhesives suffice. No specialized training or equipment necessary.

Q5: What is the expected service lifespan?

A: UV-stabilized grades in climate-controlled environments maintain performance for 8-12 years. Humidity-resistant formulations extend durability in basements/bathrooms.

WELLE Trade has over 20 years of experience in the production and processing of PE/EVA/TPE foams, so you may want to consult with them if you have any sourcing needs.