Abstract

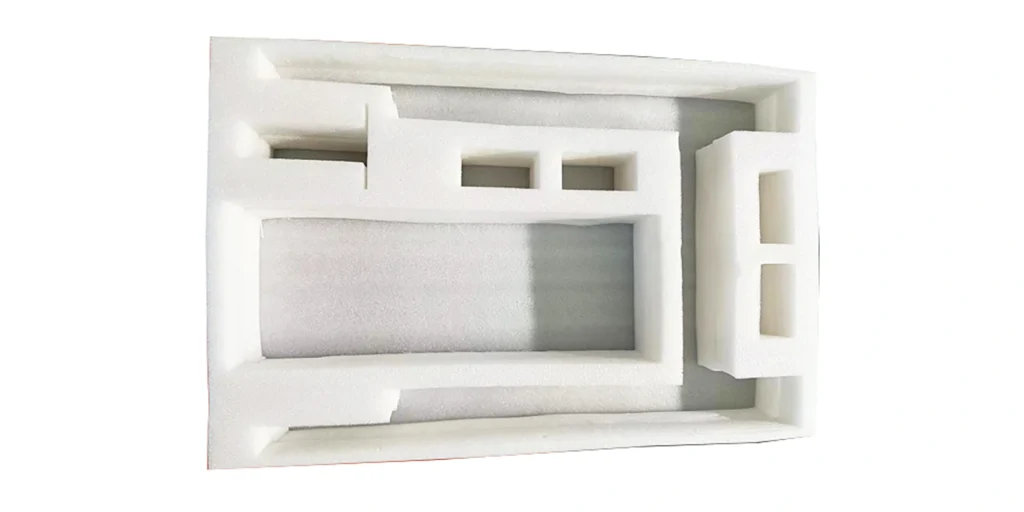

PE Foam (polyethylene foam), renowned for its lightweight and superior cushioning properties, has long been a staple in protective packaging for electronics, furniture, medical equipment, and more. As global environmental awareness grows, its recyclability and low-carbon production processes are now at the forefront of industry innovation. This article provides an in-depth analysis of PE Foam’s ecological advantages, recycling technologies, and sector-specific applications, exploring its potential to drive the packaging industry toward a sustainable future.

The Green Revolution of PE Foam: Why It’s the New Champion of Eco-Friendly Packaging?

1. Recyclability: Transforming Waste into Resources

Traditional plastic packaging faces criticism for its non-biodegradability, whereas PE Foam enables closed-loop recycling through advanced physical processing. Post-consumer PE foam is sorted, shredded, and melted into pelletized raw material, which is then repurposed for manufacturing low-demand plastic products (e.g., planters, industrial pallets), achieving a remarkable resource recovery rate exceeding 90%. Leading corporations have established “collection-remanufacturing” systems, substantially reducing virgin material consumption.

2. Low-Carbon Production: Dual Benefits of Plastic Reduction and Energy Efficiency

Compared to materials like expanded polystyrene (EPS), PE Foam production requires significantly lower energy input and eliminates the need for ozone-depleting blowing agents. Its lightweight nature further curtails carbon emissions during transportation. For instance, a global logistics firm reported a 30% reduction in packaging weight and a 15% annual carbon footprint decrease after switching to PE Foam.

3. Industry Applications: Pioneering Green Solutions

- Electronics: Brands like Apple and Samsung utilize PE Foam to safeguard delicate components while implementing take-back programs for packaging recycling.

- Cold Chain Logistics: Combining thermal insulation with recyclable design, PE Foam replaces single-use EPS in perishable food transport containers.

- Construction: As an eco-friendly acoustic barrier, PE Foam panels are repeatedly reused in renovations, minimizing construction waste.

Future Outlook: Policy and Innovation as Catalysts

The EU’s Plastics Strategy mandates 100% recyclable plastic packaging by 2030, accelerating PE Foam technology advancements. Enterprises are developing chemical recycling methods to break down PE Foam into monomer-grade materials for higher-purity regeneration. Concurrently, compostable PE Foam prototypes are undergoing pilot testing, promising breakthroughs in biodegradability.

FAQ: Addressing Key Queries on PE Foam

Q1: Is PE Foam 100% recyclable?

Current physical recycling processes handle over 90% of uncontaminated PE Foam waste, though contaminated or composite variants require additional sorting. Chemical recycling advancements aim to achieve near-total recyclability.

Q2: How does PE Foam outperform EPS (expanded polystyrene) in sustainability?

- Production: PE Foam avoids chemical blowing agents, eliminating ozone layer risks.

- Recyclability: EPS’s low density and fragility make recycling economically less viable than PE Foam.

- Carbon Footprint: PE Foam’s lightweight design reduces transport emissions, yielding 30% lower lifecycle carbon intensity.

Q3: How can consumers contribute to PE Foam recycling?

Brands increasingly label packaging with recycling instructions. Consumers may return used foam to designated collection points—e.g., IKEA’s take-back program rewards participants with discount vouchers.

Q4: Does adopting PE Foam increase corporate costs?

While initial investment may exceed conventional materials, long-term benefits include:

- Reduced raw material costs through recycling systems;

- Compliance with environmental regulations to avoid penalties;

- Enhanced brand equity and product premium potential via sustainable positioning.

WELLE Trade has over 20 years of experience in the production and processing of PE/EVA/TPE foams, so you may want to consult with them if you have any sourcing needs.