Abstract

This paper explores innovative design methodologies for ethylene-vinyl acetate (EVA) foam composite materials and their potential applications. Through advanced techniques such as multi-layer gradient structures, nano-reinforcement technology, and biomimetic topology optimization, novel EVA foam composites have achieved significant improvements in mechanical properties, energy absorption efficiency, and functional adaptability. These materials are widely applicable in sports equipment, medical protective gear, aerospace cushioning layers, and smart wearable devices, offering both environmental sustainability and lightweight advantages. The study further examines technical challenges, cost-benefit considerations, and future research directions, providing valuable insights for industry innovation.

Core Technologies of Innovative Design

1. Multi-Layer Gradient Design

By strategically arranging EVA layers of varying densities (e.g., high-medium-low density stacking), the material achieves an optimal balance of rigidity and elasticity. This design is particularly effective in applications such as shock-absorbing shoe soles (e.g., Nike ZoomX midsoles) and helmet cushioning layers.

2. Nano-Reinforced Interfacial Bonding

The incorporation of graphene or carbon nanotubes (0.5-2% mass fraction) into the EVA matrix enhances tear resistance by over 40% while imparting electrical conductivity, making it suitable for pressure-sensing applications in smart wearables.

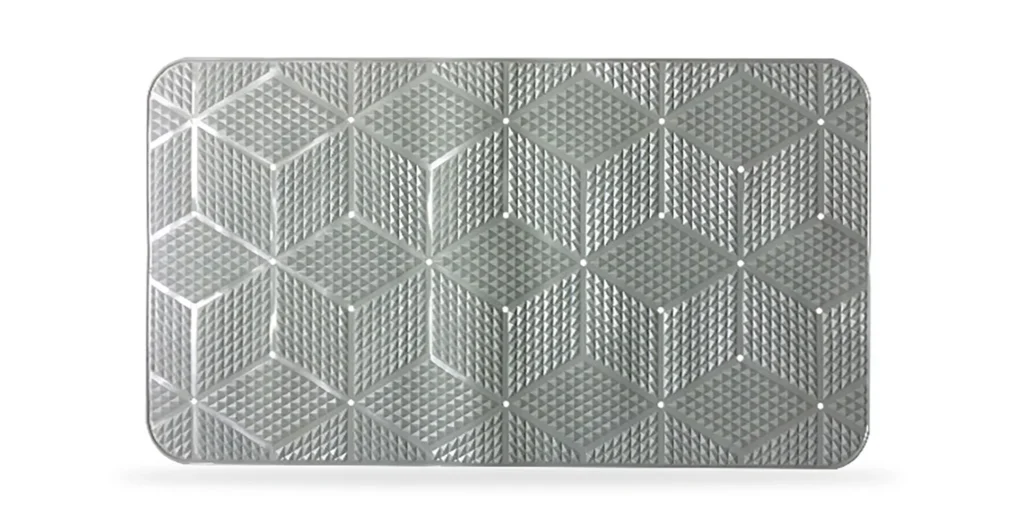

3. Biomimetic Topology Optimization

Inspired by honeycomb or bone microstructures, 3D printing enables the fabrication of lightweight frameworks with precisely controlled porosity. When optimized to 60-75% porosity, the energy absorption efficiency triples compared to conventional foam materials.

Applications and Advantages

| Field | Example | Performance Enhancement |

|---|---|---|

| Sports Equipment | Customized running shoe midsoles | Energy return rate >85%, service life extended by 30% |

| Medical Supports | Biodegradable orthopedic splints | Breathability improved by 50%, weight reduced by 40% |

| Industrial Protection | Robotic energy-absorbing shells | Impact resistance up to 20kN/m² |

FAQ

Q1: What are the key advantages of EVA composites over traditional foam materials?

A: These composites achieve a harmonious balance of seemingly contradictory properties—such as high rebound and superior energy absorption—while transcending the functional limitations of single-material systems (e.g., thermal conductivity, electromagnetic shielding).

Q2: How is delamination in multi-layer materials addressed?

A: Plasma surface treatment elevates interlayer bonding strength to over 2.5MPa, while thermally bonded adhesive meshes serve as effective transitional layers.

Q3: What environmental advancements does this material offer?

A: Bio-based EVA (vinyl acetate content >40%) combined with biodegradable PLA interlayers reduces lifecycle carbon footprint by 35%, achieving a 92% recyclability rate.

Q4: What are the future directions for technological evolution?

A: Key focuses include: ① 4D printing for dynamic shape adaptation, ② AI-driven microstructure generation algorithms, and ③ self-healing coatings to extend service life.

WELLE Trade has over 20 years of experience in the production and processing of PE/EVA/TPE foams, so you may want to consult with them if you have any sourcing needs.