EVA foam padding, or Ethylene Vinyl Acetate foam, is rapidly gaining traction across various industries, from construction to sports. This versatile material, known for its durability and cushioning properties, is revolutionizing how we approach safety, comfort, and design. In this article, we’ll explore why EVA foam is becoming increasingly popular worldwide, the key considerations for importing EVA foam padding, and the exciting customization and cutting options available.

Why EVA Foam is Gaining Popularity Worldwide

1. Versatility Across Industries

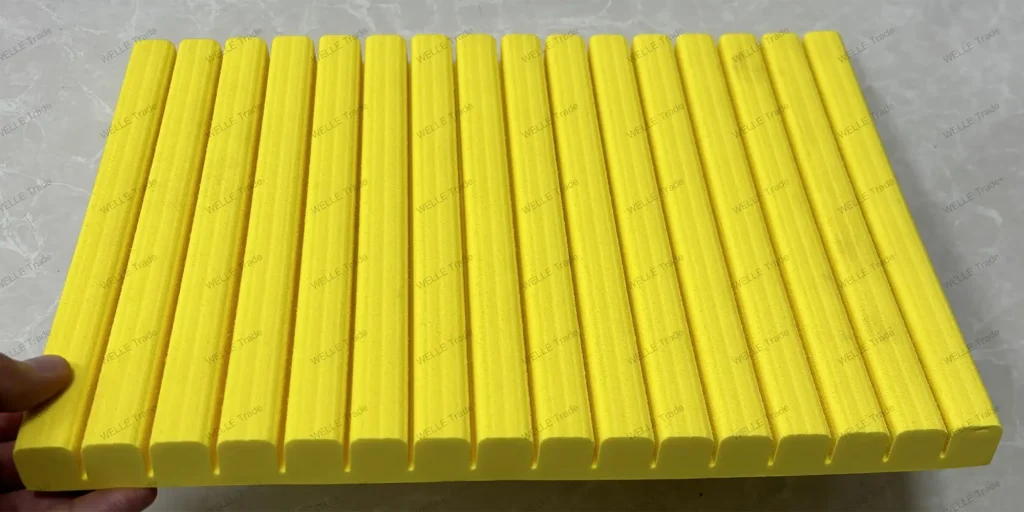

EVA foam’s adaptability is one of its most compelling features. In construction, it is used for insulation, flooring, and impact protection. The foam’s shock-absorbing qualities make it ideal for protecting structures from seismic activities and reducing noise pollution. In sports, EVA foam is utilized in equipment such as helmets, pads, and mats, enhancing safety and performance.

2. Durability and Comfort

EVA foam’s durability is another reason for its rising popularity. It resists wear and tear, providing long-lasting performance even under heavy use. Its lightweight nature and excellent cushioning properties contribute to enhanced comfort, making it a preferred choice for sports equipment and protective gear.

3. Eco-Friendly Characteristics

With growing environmental awareness, EVA foam’s eco-friendly attributes are becoming more appreciated. Many EVA foam products are recyclable, and the material can be manufactured with fewer chemicals compared to other foams. This aligns with global trends towards sustainability and greener construction practices.

Importing EVA Foam Padding: What You Need to Know

1. Understanding Regulatory Requirements

When importing EVA foam padding, it is crucial to understand the regulatory requirements of your destination country. This includes compliance with safety standards, material certifications, and import duties. Familiarize yourself with these regulations to avoid delays and ensure that your products meet all necessary standards.

2. Selecting Reliable Suppliers

Choosing a reliable supplier is key to maintaining product quality and consistency. Research potential suppliers thoroughly, checking their production capabilities, quality control processes, and customer reviews. Establish clear communication channels and request samples before making large orders to ensure the material meets your specifications.

3. Cost and Logistics

Consider the costs associated with importing EVA foam padding, including shipping, tariffs, and taxes. Evaluate different shipping options to balance cost and delivery time. Additionally, factor in the logistics of warehousing and distribution to streamline your supply chain.

Exploring the Customization and Cutting Options Available in EVA Foam

1. Customization for Specific Applications

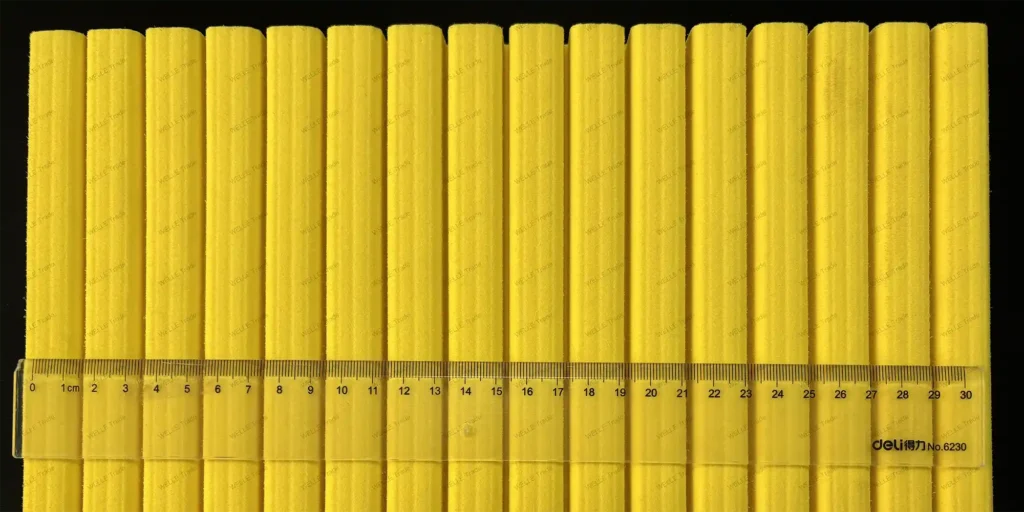

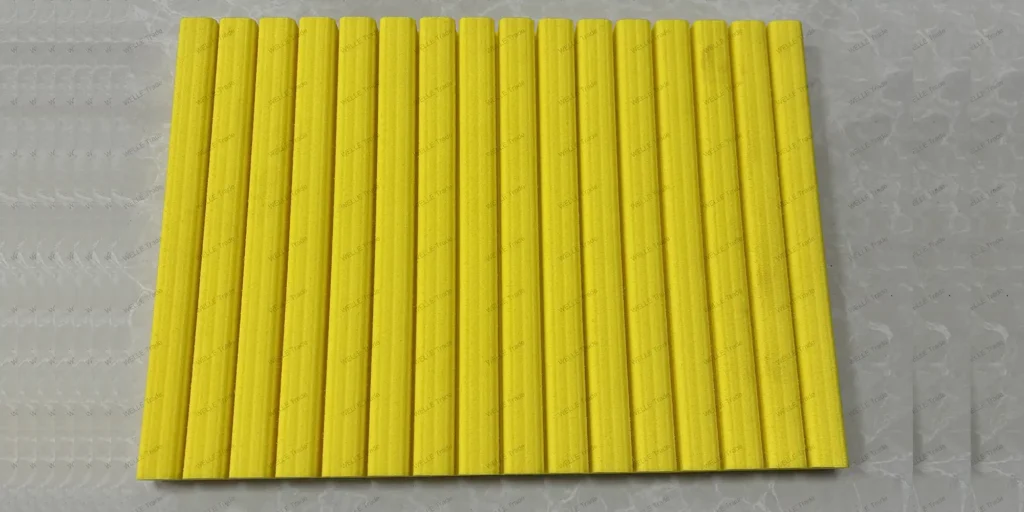

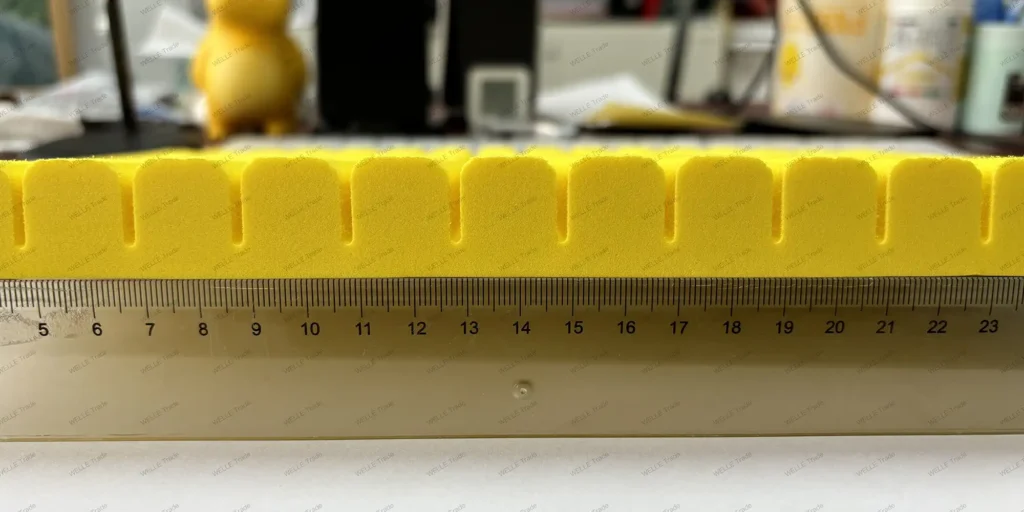

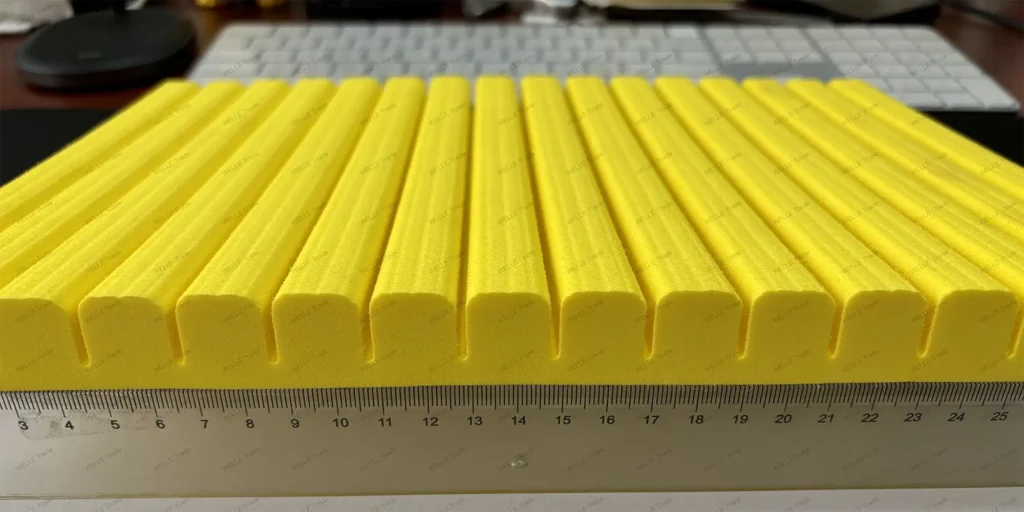

EVA foam can be customized to meet specific needs and applications. This includes altering the density, thickness, and color of the foam. Customization allows you to tailor the foam to the requirements of different industries, whether it’s for sports mats with enhanced shock absorption or construction materials with specialized insulation properties.

2. Advanced Cutting Techniques

The versatility of EVA foam is further enhanced by advanced cutting techniques. CNC (Computer Numerical Control) cutting, die-cutting, and laser cutting enable precise shaping and customization of foam pieces. These methods allow for intricate designs and tailored solutions, making EVA foam suitable for a wide range of applications.

3. Design Flexibility

The flexibility of EVA foam also extends to its design possibilities. Whether you need foam cut into specific shapes, with unique textures, or with integrated features such as interlocking tiles, the material can be adapted to fit various design requirements. This design flexibility makes EVA foam a popular choice for both functional and aesthetic applications.

EVA foam padding’s growing popularity in construction and sports can be attributed to its versatility, durability, and eco-friendly characteristics. As more industries recognize the benefits of this material, understanding the intricacies of importing EVA foam and exploring its customization options will be crucial. Whether you’re enhancing safety in sports or improving insulation in construction, EVA foam offers innovative solutions to meet diverse needs.

For anyone looking to leverage EVA foam padding’s global appeal, staying informed about regulatory requirements, selecting reliable suppliers, and exploring advanced customization options will ensure you make the most of this versatile material.

FAQ

1. What is EVA foam padding and why is it popular?

EVA foam padding, or Ethylene Vinyl Acetate foam, is a versatile material known for its durability, shock absorption, and lightweight properties. Its popularity stems from its wide range of applications in construction and sports, as well as its eco-friendly characteristics.

2. How is EVA foam used in construction?

In construction, EVA foam is used for insulation, flooring, and impact protection. Its shock-absorbing qualities help protect structures from seismic activities and reduce noise pollution.

3. What should I consider when importing EVA foam padding?

When importing EVA foam padding, consider regulatory requirements, supplier reliability, and associated costs. Ensure compliance with safety standards, select reputable suppliers, and factor in shipping and logistics expenses.

4. Can EVA foam be customized?

Yes, EVA foam can be customized in terms of density, thickness, color, and shape. Advanced cutting techniques such as CNC cutting, die-cutting, and laser cutting allow for precise customization to meet specific needs.

5. What are the eco-friendly aspects of EVA foam?

Many EVA foam products are recyclable and manufactured with fewer chemicals compared to other foams. This makes EVA foam a more sustainable choice in line with global environmental trends.

#EVAfoam #FoamPadding #ConstructionMaterials #SportsEquipment #EcoFriendlyProducts #FoamCustomization #ImportingFoam #VersatileFoam #SustainableMaterials #CuttingEdgeFoam

WELLE Trade has over 20 years of experience in the production and processing of PE/EVA/TPE foams, so you may want to consult with them if you have any sourcing needs.