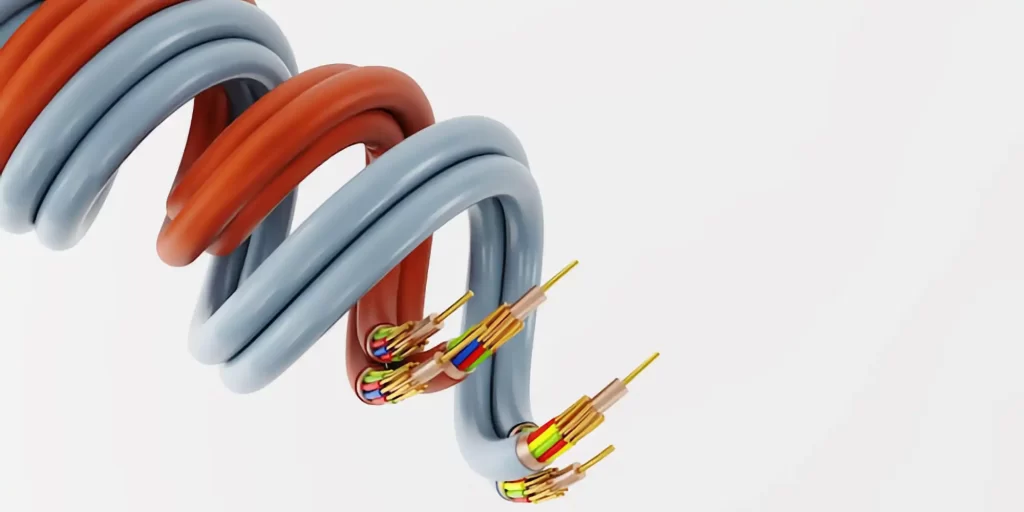

In the world of industrial and commercial applications, the protection of cables and hoses is paramount to ensure longevity, functionality, and safety. Ethylene-Vinyl Acetate (EVA) foam has emerged as a key material in this domain, renowned for its exceptional protective qualities, flexibility, and durability. This article delves into the benefits of EVA foam in cable and hose protection, highlighting its advantages and addressing frequently asked questions about its application in safeguarding essential components.

The Benefits of EVA Foam in Cable and Hose Protection

EVA foam brings several key advantages to cable and hose protection:

1. Superior Durability and Protection:

EVA foam provides excellent cushioning and shock absorption, effectively protecting cables and hoses from physical damage, abrasion, and wear.

2. Flexibility and Conformability:

Its inherent flexibility allows EVA foam to conform to various shapes and sizes of cables and hoses, ensuring a snug and secure fit.

3. Resistance to Environmental Factors:

Resistant to UV radiation, chemicals, and extreme temperatures, EVA foam ensures long-lasting performance in diverse environmental conditions.

4. Lightweight and Easy to Install:

Being lightweight, EVA foam protection solutions are easy to handle and install, reducing labor and simplifying maintenance.

5. Customizable for Specific Applications:

EVA foam can be cut and shaped to fit specific requirements, making it a versatile option for a wide range of cable and hose protection needs.

6. Enhanced Safety:

By protecting cables and hoses from damage, EVA foam aids in preventing potential hazards like electrical shorts, leaks, and other failures.

Applications of EVA Foam in Cable and Hose Protection

Industrial Machinery:

EVA foam is used to protect cables and hoses in heavy machinery, reducing the risk of damage and prolonging equipment life.

Automotive Industry:

In vehicles, EVA foam safeguards wiring and hoses against abrasion and environmental elements, contributing to vehicle reliability and safety.

Construction and Mining:

EVA foam provides robust protection for cables and hoses in harsh construction and mining environments, where exposure to abrasive materials and rough handling is common.

Marine Applications:

For marine vessels, EVA foam offers protection against saltwater corrosion and mechanical wear, ensuring the integrity of cables and hoses.

Electronics and Electrical Systems:

In electronic devices and electrical systems, EVA foam helps in organizing and protecting cables, preventing tangling and damage.

Enhancing Equipment Longevity with EVA Foam

The integration of EVA foam into cable and hose protection represents a significant advancement in industrial and commercial maintenance, focusing on durability, safety, and efficiency.

FAQs About EVA Foam in Cable and Hose Protection

Q: How does EVA foam improve the lifespan of cables and hoses?

A: EVA foam enhances the lifespan by providing a protective layer that absorbs impacts, resists abrasion, and shields against environmental factors.

Q: Is EVA foam suitable for outdoor applications?

A: Yes, EVA foam’s resistance to UV radiation and weather conditions makes it suitable for outdoor cable and hose protection applications.

Q: Can EVA foam protection be customized for different sizes and shapes?

A: Absolutely, EVA foam can be easily cut and shaped, allowing for customization to fit various sizes and configurations of cables and hoses.

Q: Are EVA foam protection solutions easy to install and maintain?

A: EVA foam solutions are generally lightweight and straightforward to install, making maintenance and adjustments simple and efficient.

In conclusion, EVA foam has become an essential material in the design and manufacture of cable and hose protection solutions, providing enhanced durability, flexibility, and safety. Its combination of protective properties, adaptability, and ease of use makes it an ideal choice for a wide range of industrial and commercial applications. As the demand for reliable and efficient protection solutions continues to grow, EVA foam-enhanced cable and hose protection products are set to play a significant role in improving the longevity and safety of essential components in various industries.