The automotive industry is a dynamic realm, always in pursuit of materials that can elevate the performance, safety, and efficiency of vehicles. Among the myriad of materials explored, EVA foam has emerged as a game-changer, especially in the domain of car gaskets and seals. This article delves deep into the world of EVA foam, highlighting its transformative role in automotive sealing solutions.

Introduction

Gaskets and seals play a pivotal role in ensuring the smooth operation of vehicles. They prevent leaks, keep contaminants out, and ensure that various automotive components function seamlessly. With the introduction of EVA foam in this sector, there has been a paradigm shift in how gaskets and seals are designed, manufactured, and implemented.

Why EVA Foam for Gaskets and Seals?

EVA foam, or Ethylene-Vinyl Acetate, is renowned for its flexibility, durability, and excellent sealing properties. When utilized in car gaskets and seals, it offers:

- Superior Sealing: EVA foam’s closed-cell structure ensures impeccable sealing, preventing any fluid or air leakage.

- Resistance to Chemicals: EVA foam is resistant to various automotive fluids, ensuring longevity and consistent performance.

- Thermal Stability: The foam remains stable across a wide temperature range, making it ideal for applications exposed to varying temperatures.

- Flexibility: EVA foam can conform to intricate shapes, ensuring a perfect fit for diverse automotive components.

Benefits of EVA Foam Gaskets and Seals

- Enhanced Performance: EVA foam seals offer a tighter fit, reducing the chances of leaks and enhancing the overall performance of the vehicle.

- Cost-Effective: EVA foam provides a premium sealing solution at a fraction of the cost of traditional materials.

- Easy Installation: The flexibility of EVA foam allows for easy installation, reducing labor costs and time.

- Durability: EVA foam gaskets and seals are designed to last, offering an extended service life compared to conventional materials.

Applications in the Automotive Industry

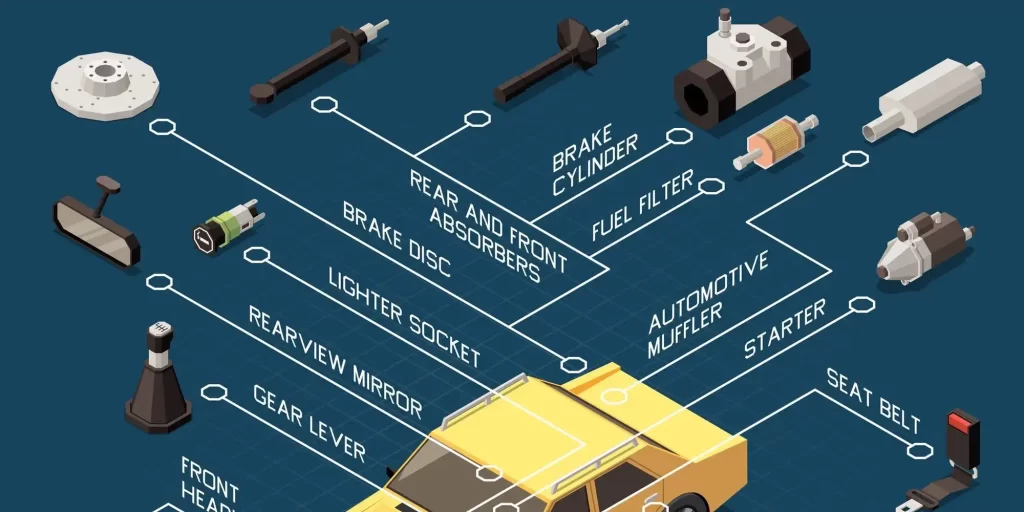

The versatility of EVA foam has led to its widespread adoption in the automotive industry. Apart from gaskets and seals, EVA foam finds applications in:

- Soundproofing solutions

- Interior padding

- Dashboard components

- Seat cushions

Future Trends and Innovations

With continuous advancements in material science and processing technologies, the potential applications of EVA foam in the automotive sector are boundless. As manufacturers strive to produce lighter, more fuel-efficient vehicles, the lightweight nature of EVA foam makes it a material of choice for future innovations.

FAQ

- How do EVA foam gaskets compare to rubber gaskets?

- EVA foam gaskets offer superior sealing, flexibility, and chemical resistance compared to traditional rubber gaskets.

- Are EVA foam seals environmentally friendly?

- Yes, EVA foam is non-toxic and recyclable, making it an eco-friendly choice.

- How do I maintain EVA foam gaskets and seals?

- EVA foam requires minimal maintenance. Regular checks for wear and tear and cleaning with a damp cloth are sufficient.

- Where can I purchase EVA foam gaskets and seals?

- Many automotive parts suppliers and specialized manufacturers offer EVA foam sealing solutions.