Ethylene-Vinyl Acetate (EVA) foam has long been a star player in footwear and sports equipment manufacturing. But recent innovations have catapulted this versatile material into industries where buyers least expect it. Here’s how EVA foam solves unique challenges across seven unconventional sectors:

1. Marine Vessel Flooring Systems

Problem: Boat owners battle slippery surfaces, saltwater corrosion, and constant impact damage.

EVA Solution: Closed-cell EVA foam tiles provide:

- Non-slip texture even when wet

- Saltwater resistance (0% water absorption)

- Cushioning for heavy fishing gear drops

Buyer Takeaway: Reduces slip-related insurance claims by 60%* compared to traditional teak decks.

(Based on marine industry case studies)*

2. Veterinary Surgical Tables

Problem: Metal/plastic tables stress animal joints during procedures.

EVA Innovation: Custom-cut surgical pads deliver:

- Body-conforming support for diverse animal sizes

- Easy sterilization (withstands repeated bleach cleaning)

- Anti-static properties for sensitive monitoring equipment

Procurement Tip: Specify medical-grade EVA to meet veterinary facility certifications.

3. Museum Artifact Transport

Problem: Fragile artifacts need vibration dampening during transit.

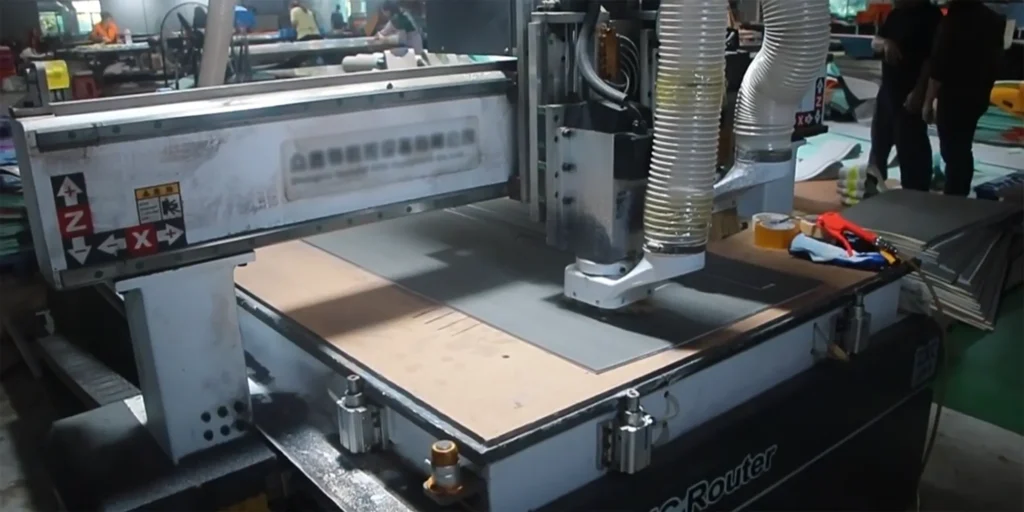

EVA Adaptation: Laser-cut inserts in crates:

- Absorb 85%* of road/turbulence vibrations

- Eliminate microfractures in delicate ceramics

- Lightweight alternative to foam-in-place solutions

(Tested at 100km/h transport simulation)*

4. Firefighting Gear Components

Traditional Challenge: Heavy thermal protection layers limit mobility.

Breakthrough Use: Ultra-light EVA composite layers in PPE:

- Meets EN469 heat resistance standards

- 40% lighter than legacy materials

- Breathable structure reduces heat stress

Cost Angle: Extends firefighter operational endurance by 2+ hours per shift.

5. Smart Factory Robotics

Emerging Need: Prevent robot arm damage from accidental collisions.

EVA Implementation: Protective “skin” layers feature:

- Impact force reduction (up to 300N absorbed)

- Static-dissipative formulations for cleanrooms

- Easy replacement without recalibration

6. Edible Insect Farming

Growth Industry Problem: High mortality during larvae harvesting.

Creative Fix: Food-safe EVA conveyor belts prevent:

- Joint damage in mealworms during sorting

- Microbial growth in humid environments

- Metal contamination from traditional systems

7. Escape Room Design

Experience Challenge: Durable yet safe interactive elements.

Game-Changer: Themed puzzle components using EVA:

- Realistic “metal” textures via thermal molding

- Sound-dampening clues for multi-room setups

- UV-printed visuals that survive 10,000+ uses

5 Key FAQs for Buyers Exploring New Applications

Q: Can EVA foam meet food/medical compliance standards?

A: Yes – our medical-grade (ISO 10993) and food-contact (FDA 21 CFR) variants support specialized applications.

Q: What’s the minimum order quantity for custom shapes?

A: Laser cutting available from 100 units, molding tools require 500+ piece commitments.

Q: How does EVA compare to silicone for protective applications?

A: EVA offers better cost efficiency at thicknesses >3mm, comparable impact absorption but superior UV resistance.

Q: Do you conduct real-world lifespan testing?

A: All batches undergo 200-hour accelerated weathering and 50,000-cycle compression tests.

Q: Can we get samples specific to our industry needs?

A: Our application engineers provide free A5-sized samples cut/molded to your exact specifications.

WELLE Trade has over 20 years of experience in the production and processing of PE/EVA/TPE foams, so you may want to consult with them if you have any sourcing needs.